Die Science: Piercing, cutting aluminum without slivers

By A Mystery Man Writer

Last updated 28 May 2024

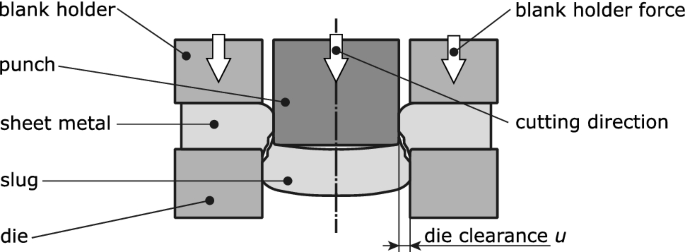

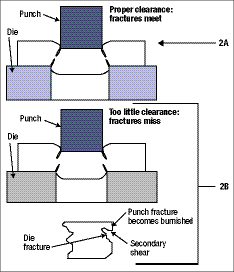

Slivers are the result of the aluminum interfacing with the cutting sections or punches. To reduce the production of slivers the severity of friction at the point where the two surfaces interface must be reduced. The general rule for cutting materials is the softer the metal the smaller the cutting clearance.

Scalpel with 10 x No.10 and 10 x No.23 carbon steel knife blades included Super sharpness for the blade edge,cut anything with great ease Perfect for

Modelcraft Tool Hobby Knife Set with No 10 and 23 (10 Each) Sterile Scalpel Blades for Cutting Materials Paper Leather,DIY

PDF) Notch Shear Cutting of Aluminum Alloys

Influence of cutting parameters on mechanisms causing slug pulling

Stamping Die Essentials: Processing the part

Piercing Die For Sheet Metal Component

Art Hedrick: Contributing Writer at Dieology LLC - Page 3

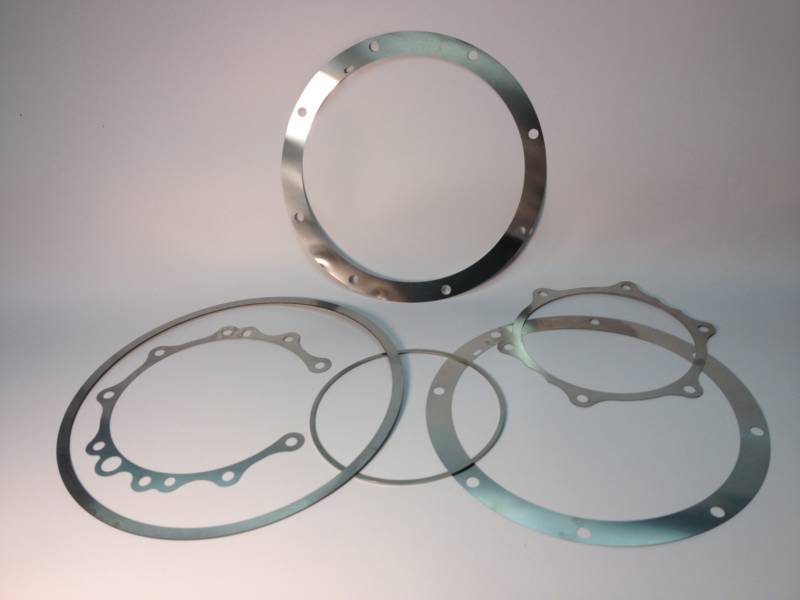

Aluminum – Die Cut Products – Precision Stamping & Gasket Fabrication

Stamping Die Essentials: Processing the part

Burning Question: What happens if you don't remove a splinter

Manufacturing Standards

10 Home Remedies To Get A Splinter Out Easily With No Pain

Cutting lubricant formulated for use on aluminum

Recommended for you

-

Grid Metal Die Cuts,Cutting Dies for Card Making Clearance,Embossing Dies for Scrapbooking, DIY Album Paper Cards Art Craft Decoration28 May 2024

Grid Metal Die Cuts,Cutting Dies for Card Making Clearance,Embossing Dies for Scrapbooking, DIY Album Paper Cards Art Craft Decoration28 May 2024 -

Cutting Clearance MetalForming Magazine Article28 May 2024

Cutting Clearance MetalForming Magazine Article28 May 2024 -

Die Cuts Moulding Strips 8 Piece Lot Scrapbook Craft Letters Making Memories28 May 2024

Die Cuts Moulding Strips 8 Piece Lot Scrapbook Craft Letters Making Memories28 May 2024 -

Blog Entries That Mention Spellbinders - Wizard Embossing and Die Cutting System, CLEARANCE28 May 2024

Blog Entries That Mention Spellbinders - Wizard Embossing and Die Cutting System, CLEARANCE28 May 2024 -

2024 Newest Stamps and Die Cuts for Card Making, Scrapbooking & Stamping Supplies, Stamp and Die Sets, Arts and Crafts Die Cuts Clearance for28 May 2024

2024 Newest Stamps and Die Cuts for Card Making, Scrapbooking & Stamping Supplies, Stamp and Die Sets, Arts and Crafts Die Cuts Clearance for28 May 2024 -

Oval Tag Metal Cutting Dies Stencil DIY Scrapbooking28 May 2024

Oval Tag Metal Cutting Dies Stencil DIY Scrapbooking28 May 2024 -

2024 Newest Stamps and Die Cuts for Card Making, Scrapbooking & Stamping Supplies, Stamp and Die Sets, Arts and Crafts Die Cuts Clearance for28 May 2024

2024 Newest Stamps and Die Cuts for Card Making, Scrapbooking & Stamping Supplies, Stamp and Die Sets, Arts and Crafts Die Cuts Clearance for28 May 2024 -

Love You Metal Cutting Dies Scrapbooking Stencil Die Cuts Card Embossing Album Scrapbooking Die Cuts Clearance28 May 2024

Love You Metal Cutting Dies Scrapbooking Stencil Die Cuts Card Embossing Album Scrapbooking Die Cuts Clearance28 May 2024 -

Newest Scrapbooking, Cardmaking and Crafting Inspiration28 May 2024

Newest Scrapbooking, Cardmaking and Crafting Inspiration28 May 2024 -

Car with Summer Board Metal Cutting Dies Embossing Stencil DIY Scrapbooking Greeting Card Making Album Template Dies Scrapbooking Die Cuts Clearance28 May 2024

Car with Summer Board Metal Cutting Dies Embossing Stencil DIY Scrapbooking Greeting Card Making Album Template Dies Scrapbooking Die Cuts Clearance28 May 2024

You may also like

-

Vallejo Paints - A-Z Toy Hobby28 May 2024

Vallejo Paints - A-Z Toy Hobby28 May 2024 -

Surgical Tape Transpore 1 Inch X 30 Feet28 May 2024

Surgical Tape Transpore 1 Inch X 30 Feet28 May 2024 -

Simax Glass Measuring Cup | Durable Borosilicate Glass, Easy to Read Metric Measurements- Liter, Milliliter, Ounce, Sugar Grams, Flour Grams, Drip28 May 2024

Simax Glass Measuring Cup | Durable Borosilicate Glass, Easy to Read Metric Measurements- Liter, Milliliter, Ounce, Sugar Grams, Flour Grams, Drip28 May 2024 -

60 Things to Do When You're Bored at Home28 May 2024

60 Things to Do When You're Bored at Home28 May 2024 -

BearTOOLS Tool Lanyard with Single Carabiner and Adjustable Loop End, Standard Length, Maximum Weight Limit 8kg / 17.6lb, Aluminum Screw Lock28 May 2024

BearTOOLS Tool Lanyard with Single Carabiner and Adjustable Loop End, Standard Length, Maximum Weight Limit 8kg / 17.6lb, Aluminum Screw Lock28 May 2024 -

Cabinet Small Storage Box Jewelry Wooden 5 Drawer Style Teak Box28 May 2024

Cabinet Small Storage Box Jewelry Wooden 5 Drawer Style Teak Box28 May 2024 -

Knitting Machine, Knitting Machine 48 Needle Smart Loom with Row Counter, Knitting Board Rotary Double Loom (48B)28 May 2024

Knitting Machine, Knitting Machine 48 Needle Smart Loom with Row Counter, Knitting Board Rotary Double Loom (48B)28 May 2024 -

Masking Tape28 May 2024

Masking Tape28 May 2024 -

Fabric Pen Refill for Sewing Erasable - 100Pcs Fabric Markers for Sewing Pens for Fabric Ink Refill Silver Fabric Marker Pen Refill - Sewing Supplies28 May 2024

Fabric Pen Refill for Sewing Erasable - 100Pcs Fabric Markers for Sewing Pens for Fabric Ink Refill Silver Fabric Marker Pen Refill - Sewing Supplies28 May 2024 -

Heavy Duty Bandage Cast Shears - North Coast Medical28 May 2024

Heavy Duty Bandage Cast Shears - North Coast Medical28 May 2024