When and How to Sharpen Circular Saw Blade

By A Mystery Man Writer

Last updated 29 Apr 2024

Learn the basics on how to sharpen a circular saw blade and when to do it. Get excited to keep your tools in peak condition with this handy guide.

Ryker Hardware creates High-Quality Tools, Specializing in Oscillating Multi Tool Blades. Ryker supports the trade professionals, by providing quality, reasonably priced multi tool blades. Our tools are designed for the consumer, the hobbyist and the professional.

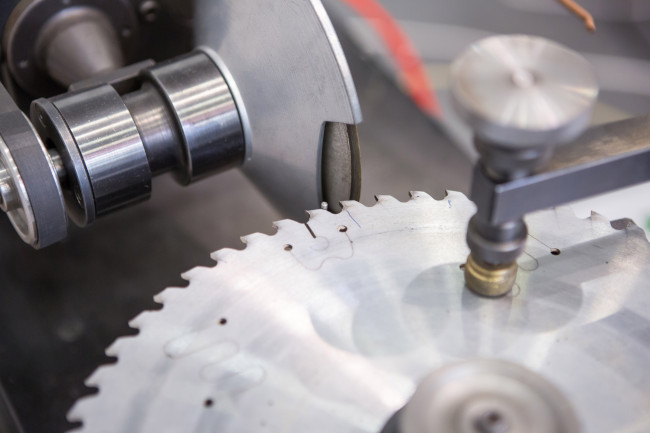

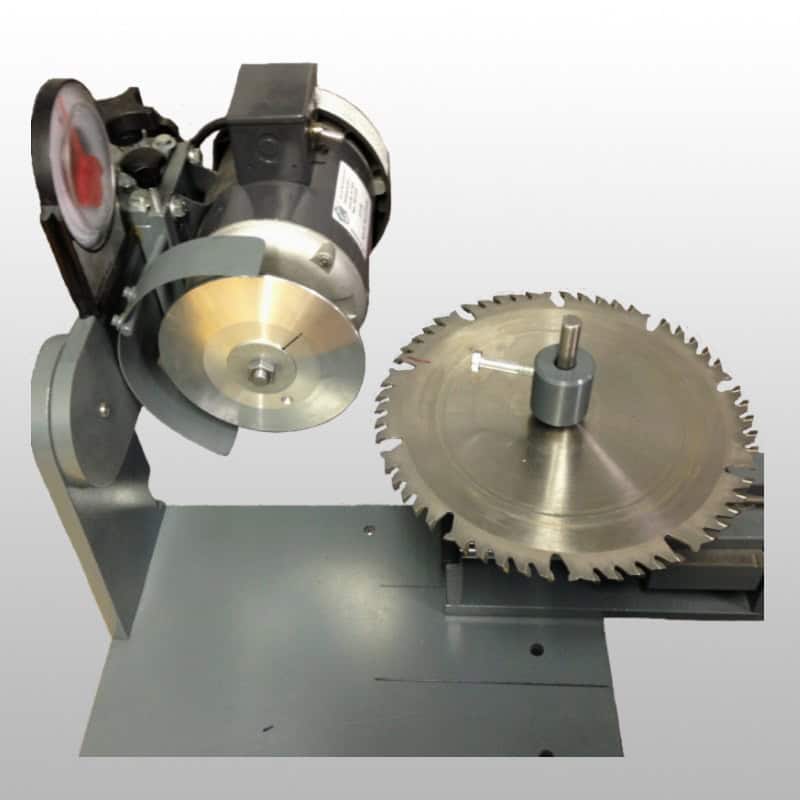

Circular saw blade sharpening is important to keep your blade sharp and ready to handle more tasks. It’s necessary to maintain your blade on regular basis to help prolong the lifespan of the blade and reduce the effort of using a dull blade. Buying a new blade simply because your blade is dull is a waste of a blade since you can bring the old one back to life by following simple steps. Too many people may opt to just buy a new blade simply because they find sharpening a gruelingly tiresome and they may have no past experience in sharpening blades. Frankly, sharpening a blade is a step-by-step process that requires keen concentration on the condition of your blade. Folks are eager to work with a sharp circular blade to make work easier and totally hassle-free. Before you replace your circular blade consider sharpening your old blade to save time and resources. The blade sharpeners are affordable and available in many stores around the country. For less than $100 you will have a sharpening tool that will serve you well for quite some time. Circular blades require special skills in order to be able to sharpen them well. If it becomes too laborious, you can take it to an expert who will sharpen it for you. Leaving the blade’s teeth uniform will be hard to manage depending on your sharpening skills. It may take you a couple of weeks—even months—for you to sharpen your circular saw blade. The machinery required to sharpen the circular blades are specialized to leave your newly-sharpened blade to maintain its uniform edges and make the blade perfect to get back in business. In case you are in a large joinery shop, it will be assistive to get to know the art of sharpening your own blades instead of hiring help. Here are some circular blade sharpeners that make your sharpening much easier: 120-Volt Circular Saw Blade Sharpener OrangeA Circular Saw Blade Sharpener Techtongda Circular Saw Blade Grinder Sharpener Universal Circular Saw Blade Sharpener ELEOPTION Circular Saw Blade Grinder Rotary Angle Mill Sharpener It is recommended that you clean the blade before the process of sharpening starts. Most of the blades sold today are silicon carbide conjoined onto a steel plate. Thorough cleaning of you saw blade makes your task of sharpening much easier and faster. At times, many people tend to think that the saw blade is dull, but it may be just dirty. Using soap to soak it and then make use of toothbrush to clean up the teeth will help a big deal. When you are using the toothbrush or a Scotch pad, ensure that you are rubbing the dirt off with the direction of the blade and not against to avoid accidents like cutting yourself. Once the cleaning is done and you’ve managed to scrub up the blade, ensure that you dry it thoroughly using a drier or lubricant to protect the blade from the dirt that piles up in the future. After the thorough cleaning of the blade, you will be able to know whether the blade needs to be sharpened or not. Reinstall the blade back on the saw and carefully check the wood moving across it. If the amount of wood moving across the blade is decelerating (or it’s becoming hard to move leaving rough cuts) or you notice burns on the edges of the wood, then your blade is dull and requires sharpening. Steps to efficiently sharpening your circular blade: Removing the blade. Removing the blade is an easy task in order to efficiently sharpen it with less hassle. Most circular saw blades have a release switch which helps when it comes to removing your blade. Some old models may require you to be armed with a wrench to loosen it from the bolts that hold it in place. Hold the blade with a vice grip. Have a secure grip of your blade with a vice grip facing upwards facing the blade teeth towards you. You need to be careful with how tight you hold the blade to avoid bending it out of shape. Make Marks to know the sharpening progress. Making marks prevents sharpening the teeth more than once. The marks should be made on top of the blade to avoid double sharpening of a particular part of the blade. The sharpener used may be a file and should be held at an angle for better results. Make up-down strokes four to five times (repeat with the same number of strokes) consistently and as you continue, you will be able to see progress. The process may require you to change the file used since they wear out as you continue. Stay keen on the Bevels. As always, bevels are on the surface of the blade and thus, stay keen on them. It is important to skip a blade and go to the following bevels, repeat the process until you do all around your blade. Repeat on the other side of the blade. After you get around the blade, turn it over and repeat the process from the third step making the marks to guide you on the progress so far. Final file. After you go through the above tips successfully, file the tips of your blade’s booth back and forth across the edges on every tip. This step is important and you don’t need to overdo then wear your file off. When you finish filing the tips of the blade, you are good to go! Install the blade back in the saw. Depending on how you removed the blade, follow the step and install it back in the saw until it holds securely. Slide the saw blade back onto the saw making sure that the teeth are in the direction that it rotates. If there are nuts, tighten them by hand then take the wrench and finish tightening without over-tightening it. There are professionals as saw sharpeners who are equipped with the necessary tools for the task. Provided your blade is in a good condition, with no teeth missing or it suffers from chips, learning to sharpen the blade on your own is achievable and the skill will be helpful and worthwhile in any future re-sharpening.

Ryker Hardware creates High-Quality Tools, Specializing in Oscillating Multi Tool Blades. Ryker supports the trade professionals, by providing quality, reasonably priced multi tool blades. Our tools are designed for the consumer, the hobbyist and the professional.

Circular saw blade sharpening is important to keep your blade sharp and ready to handle more tasks. It’s necessary to maintain your blade on regular basis to help prolong the lifespan of the blade and reduce the effort of using a dull blade. Buying a new blade simply because your blade is dull is a waste of a blade since you can bring the old one back to life by following simple steps. Too many people may opt to just buy a new blade simply because they find sharpening a gruelingly tiresome and they may have no past experience in sharpening blades. Frankly, sharpening a blade is a step-by-step process that requires keen concentration on the condition of your blade. Folks are eager to work with a sharp circular blade to make work easier and totally hassle-free. Before you replace your circular blade consider sharpening your old blade to save time and resources. The blade sharpeners are affordable and available in many stores around the country. For less than $100 you will have a sharpening tool that will serve you well for quite some time. Circular blades require special skills in order to be able to sharpen them well. If it becomes too laborious, you can take it to an expert who will sharpen it for you. Leaving the blade’s teeth uniform will be hard to manage depending on your sharpening skills. It may take you a couple of weeks—even months—for you to sharpen your circular saw blade. The machinery required to sharpen the circular blades are specialized to leave your newly-sharpened blade to maintain its uniform edges and make the blade perfect to get back in business. In case you are in a large joinery shop, it will be assistive to get to know the art of sharpening your own blades instead of hiring help. Here are some circular blade sharpeners that make your sharpening much easier: 120-Volt Circular Saw Blade Sharpener OrangeA Circular Saw Blade Sharpener Techtongda Circular Saw Blade Grinder Sharpener Universal Circular Saw Blade Sharpener ELEOPTION Circular Saw Blade Grinder Rotary Angle Mill Sharpener It is recommended that you clean the blade before the process of sharpening starts. Most of the blades sold today are silicon carbide conjoined onto a steel plate. Thorough cleaning of you saw blade makes your task of sharpening much easier and faster. At times, many people tend to think that the saw blade is dull, but it may be just dirty. Using soap to soak it and then make use of toothbrush to clean up the teeth will help a big deal. When you are using the toothbrush or a Scotch pad, ensure that you are rubbing the dirt off with the direction of the blade and not against to avoid accidents like cutting yourself. Once the cleaning is done and you’ve managed to scrub up the blade, ensure that you dry it thoroughly using a drier or lubricant to protect the blade from the dirt that piles up in the future. After the thorough cleaning of the blade, you will be able to know whether the blade needs to be sharpened or not. Reinstall the blade back on the saw and carefully check the wood moving across it. If the amount of wood moving across the blade is decelerating (or it’s becoming hard to move leaving rough cuts) or you notice burns on the edges of the wood, then your blade is dull and requires sharpening. Steps to efficiently sharpening your circular blade: Removing the blade. Removing the blade is an easy task in order to efficiently sharpen it with less hassle. Most circular saw blades have a release switch which helps when it comes to removing your blade. Some old models may require you to be armed with a wrench to loosen it from the bolts that hold it in place. Hold the blade with a vice grip. Have a secure grip of your blade with a vice grip facing upwards facing the blade teeth towards you. You need to be careful with how tight you hold the blade to avoid bending it out of shape. Make Marks to know the sharpening progress. Making marks prevents sharpening the teeth more than once. The marks should be made on top of the blade to avoid double sharpening of a particular part of the blade. The sharpener used may be a file and should be held at an angle for better results. Make up-down strokes four to five times (repeat with the same number of strokes) consistently and as you continue, you will be able to see progress. The process may require you to change the file used since they wear out as you continue. Stay keen on the Bevels. As always, bevels are on the surface of the blade and thus, stay keen on them. It is important to skip a blade and go to the following bevels, repeat the process until you do all around your blade. Repeat on the other side of the blade. After you get around the blade, turn it over and repeat the process from the third step making the marks to guide you on the progress so far. Final file. After you go through the above tips successfully, file the tips of your blade’s booth back and forth across the edges on every tip. This step is important and you don’t need to overdo then wear your file off. When you finish filing the tips of the blade, you are good to go! Install the blade back in the saw. Depending on how you removed the blade, follow the step and install it back in the saw until it holds securely. Slide the saw blade back onto the saw making sure that the teeth are in the direction that it rotates. If there are nuts, tighten them by hand then take the wrench and finish tightening without over-tightening it. There are professionals as saw sharpeners who are equipped with the necessary tools for the task. Provided your blade is in a good condition, with no teeth missing or it suffers from chips, learning to sharpen the blade on your own is achievable and the skill will be helpful and worthwhile in any future re-sharpening.

EAST END SHARPENING SERVICE CIRCULAR SAW BLADE CARBIDE TIPPED 50 TOOTH 10

How to sharpen a circular saw in 1 minute. The saw sharpens itself

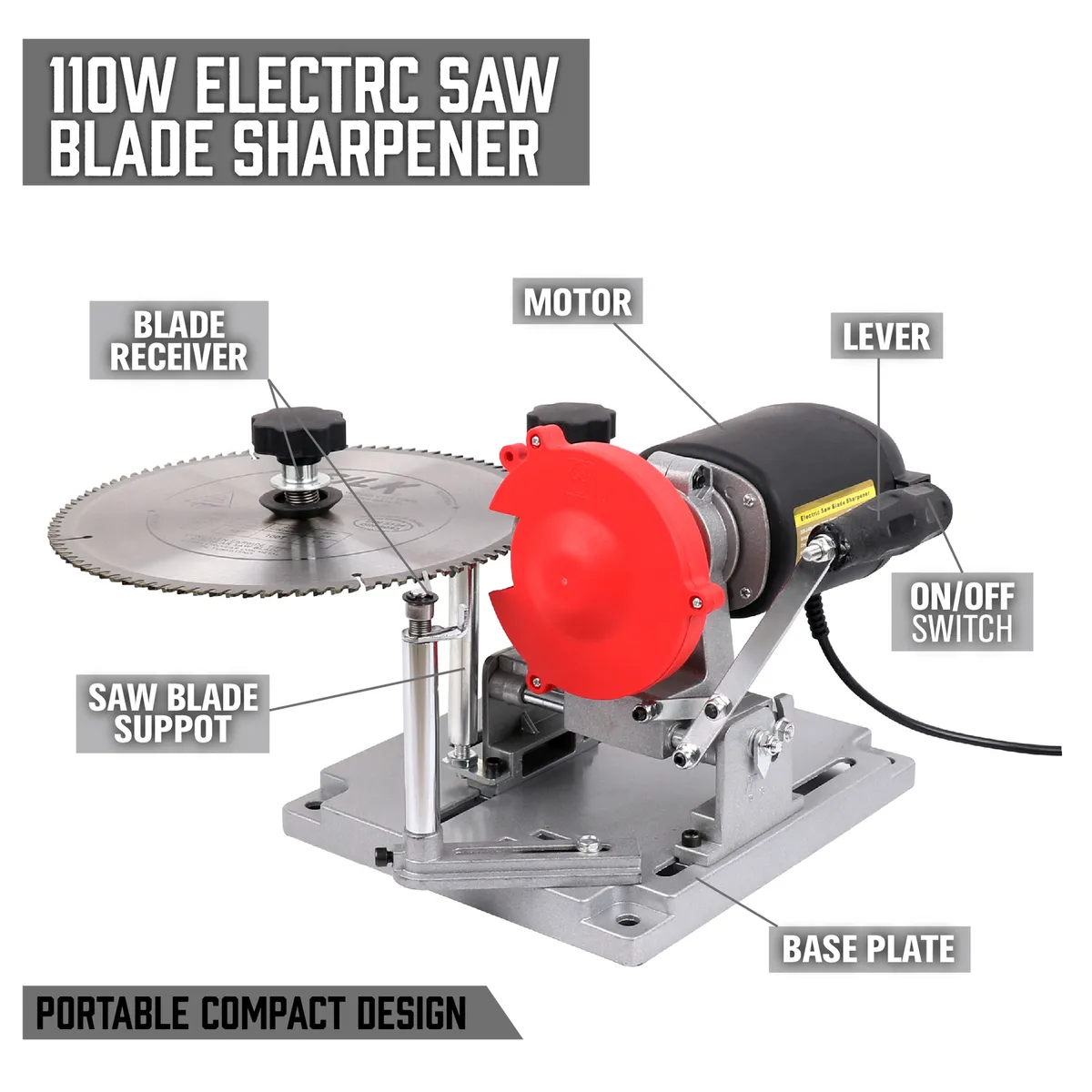

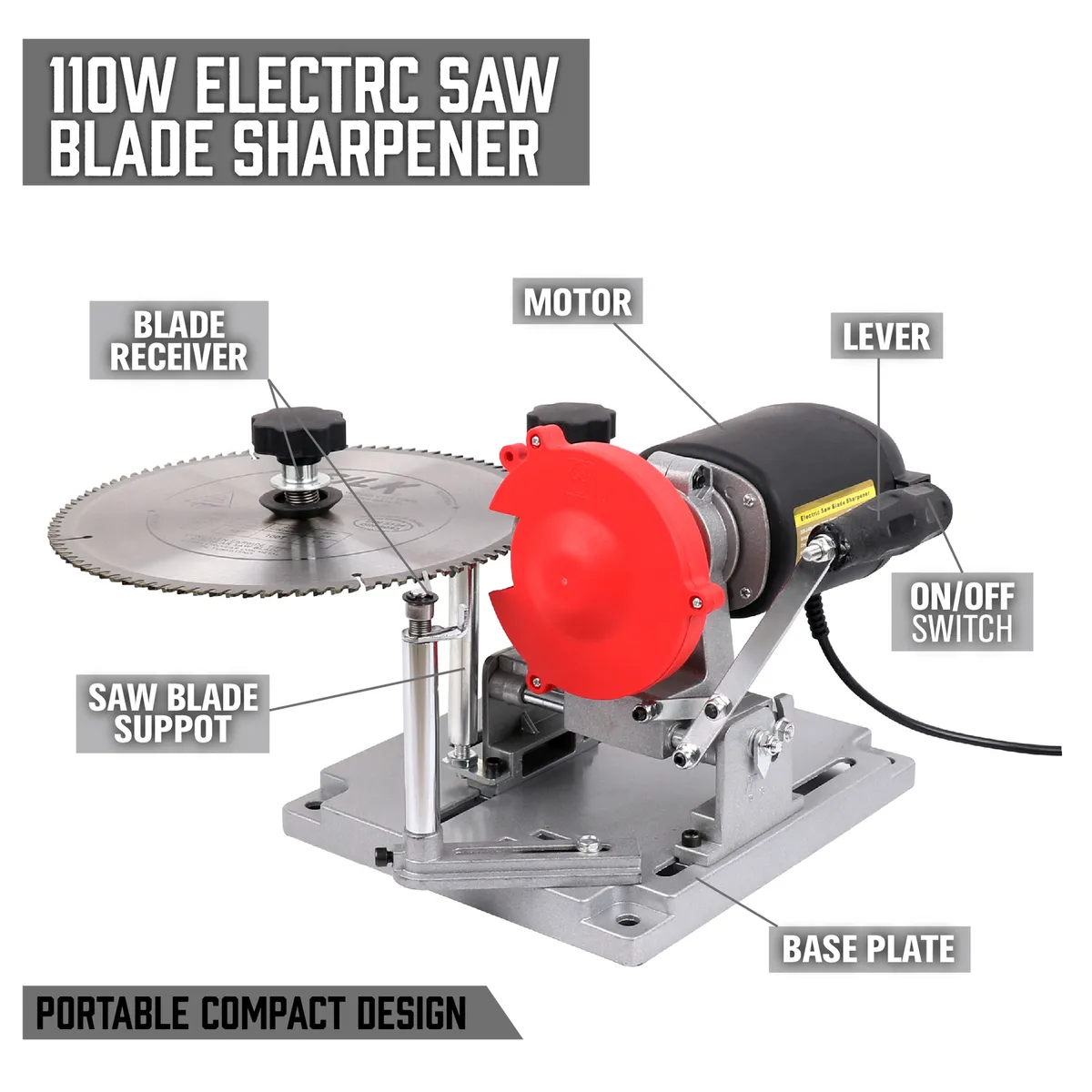

5300RPM Electric Circular Saw Blade Sharpener 110W Sharpening Fits Dia. 90-400mm

Circular Saw Blade/Router/Drill Bit Sharpening with DREMEL , PART 1

Blade Sharpening, Charlotte, NC

Sharpening a carbide tip circular saw blade. Step #1 #bobssharpening #neveradullmoment #mentorsharp #sawsharpening #sharpening #sharpeningservice, By Bob's Sharpening And Grinding - Mentor, Ohio

How to Sharpen a Circular Saw Blade: 5 Easy-to-Follow Steps

Sharpening Circular Saw Blades – Mother Earth News

How To Sharpen Table Saw Blades (The Easy Way)

High Efficiency Robot Auto Loading Tct Circular Saw Blade Sharpener - China Saw Blade Sharpener, Saw Blade Sharpening Machine

Circular saw blade sharpening machine

HSS Cold Saw Blade Sharpening Freud Certified Saw Blade Sharpener

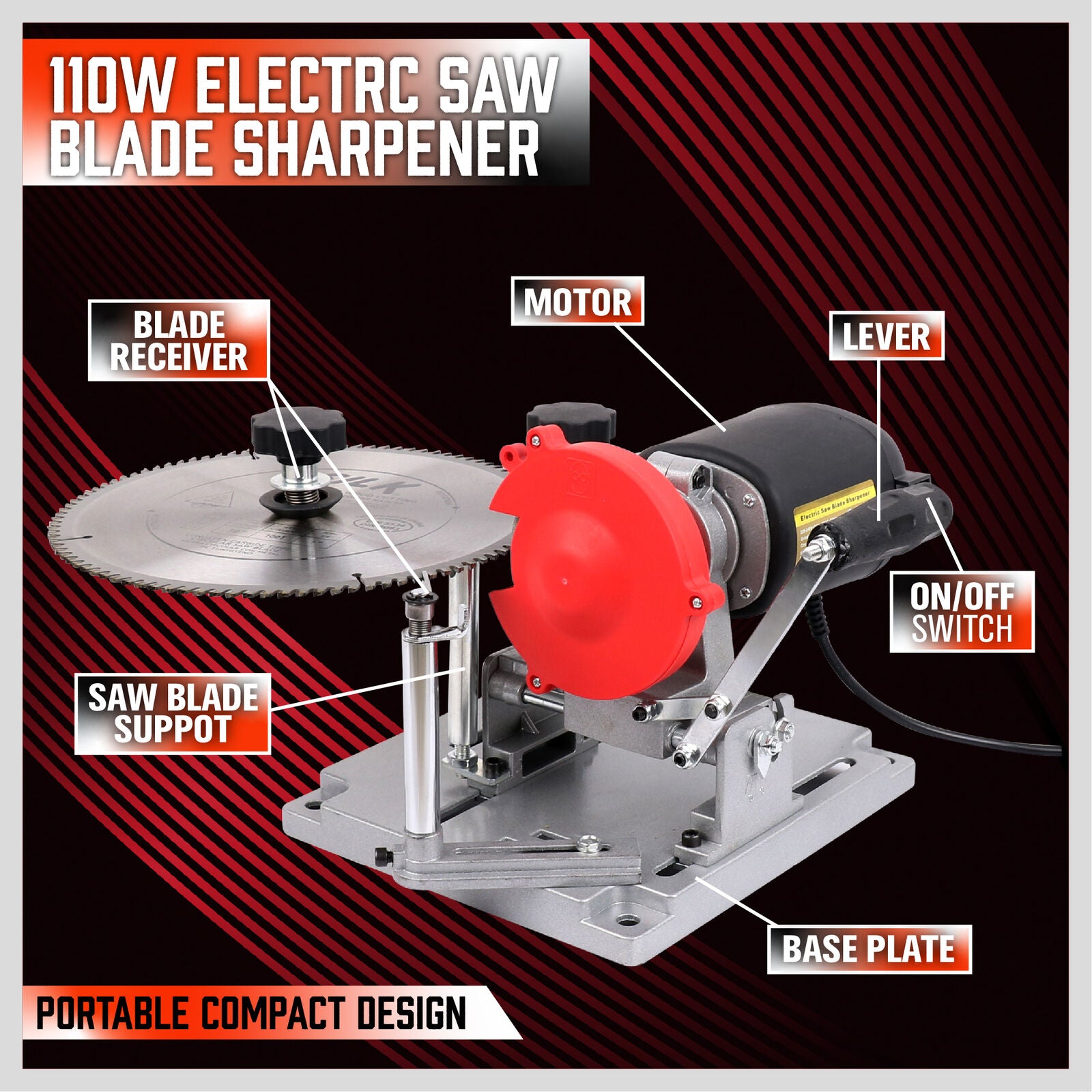

5300RPM Electric Circular Saw Blade Sharpener 110W Sharpening Fits Dia. 90-400mm

How to Sharpen a Carbide Saw Blade

Dynashape saw blade sharpening service - from the west midlands and throughout the UK.

Recommended for you

-

AV-40 Saw Blade Sharpening Machine29 Apr 2024

AV-40 Saw Blade Sharpening Machine29 Apr 2024 -

INTBUYING Round Circular Saw Blade Grinder Machine Rotary Angle Mill Sharpener for Sharpening Carbide Tipped Saw Blades (Water Injection Grinder 220V29 Apr 2024

INTBUYING Round Circular Saw Blade Grinder Machine Rotary Angle Mill Sharpener for Sharpening Carbide Tipped Saw Blades (Water Injection Grinder 220V29 Apr 2024 -

VEVOR Circular Saw Blade Sharpener Grinder 370W 3600RPM & 5-Inch Grinding Wheel29 Apr 2024

VEVOR Circular Saw Blade Sharpener Grinder 370W 3600RPM & 5-Inch Grinding Wheel29 Apr 2024 -

5300RPM Electric Circular Saw Blade Sharpener 110W Sharpening Fits Dia. 90-400mm29 Apr 2024

5300RPM Electric Circular Saw Blade Sharpener 110W Sharpening Fits Dia. 90-400mm29 Apr 2024 -

Gamut Automatic Circular Saw Blade Sharpening Machine, Control Unit: Gear Box And Electrical at Rs 275200/piece in Dombivli29 Apr 2024

Gamut Automatic Circular Saw Blade Sharpening Machine, Control Unit: Gear Box And Electrical at Rs 275200/piece in Dombivli29 Apr 2024 -

Tool Sharpening, Charlotte, NC29 Apr 2024

Tool Sharpening, Charlotte, NC29 Apr 2024 -

240V CIRCULAR SAW BLADE SHARPENER TUNGSTEN BLADE DIAMOND WHEEL GRINDER MACHINE29 Apr 2024

240V CIRCULAR SAW BLADE SHARPENER TUNGSTEN BLADE DIAMOND WHEEL GRINDER MACHINE29 Apr 2024 -

Saw Blade Sharpener - tools - by owner - sale - craigslist29 Apr 2024

Saw Blade Sharpener - tools - by owner - sale - craigslist29 Apr 2024 -

PURROS PG-Q10 Circular Saw Blade Sharpening Machine, Cheap Saw Blade Grinder for Sale - Purros Machinery Co.,Ltd.29 Apr 2024

PURROS PG-Q10 Circular Saw Blade Sharpening Machine, Cheap Saw Blade Grinder for Sale - Purros Machinery Co.,Ltd.29 Apr 2024 -

110W High-Speed Electric Blade Sharpener - Precision Circular Saw Shar – SedyOnline29 Apr 2024

110W High-Speed Electric Blade Sharpener - Precision Circular Saw Shar – SedyOnline29 Apr 2024

You may also like

-

300 Count White 4 Inch Lollipop Sticks,Sucker Stick for Cake Pops ,Cookies,Candy,Chocolate,Party29 Apr 2024

300 Count White 4 Inch Lollipop Sticks,Sucker Stick for Cake Pops ,Cookies,Candy,Chocolate,Party29 Apr 2024 -

Cheap 10mm Colorful Pom pom Ball Plush Mixed Color Creative Kids Handmade Material Glitter Foam Ball DIY Craft Supplies29 Apr 2024

Cheap 10mm Colorful Pom pom Ball Plush Mixed Color Creative Kids Handmade Material Glitter Foam Ball DIY Craft Supplies29 Apr 2024 -

Make a DIY Junk Drawer Organizer on the Cheap - Curbly29 Apr 2024

Make a DIY Junk Drawer Organizer on the Cheap - Curbly29 Apr 2024 -

WIRE LOOPER Pliers Tool, Wire Wrapping Tool, Jewelry Pliers, makes loo29 Apr 2024

WIRE LOOPER Pliers Tool, Wire Wrapping Tool, Jewelry Pliers, makes loo29 Apr 2024 -

50pcs Tassel Pendant Keychain Tassels Tiny Tassels Earring Tassel Crochet Tassels DIY Keyring Tassel Tassels for Crafts Handmade Tassels Bulk Jewelry29 Apr 2024

50pcs Tassel Pendant Keychain Tassels Tiny Tassels Earring Tassel Crochet Tassels DIY Keyring Tassel Tassels for Crafts Handmade Tassels Bulk Jewelry29 Apr 2024 -

52,900+ Red Cloth Stock Videos and Royalty-Free Footage - iStock29 Apr 2024

52,900+ Red Cloth Stock Videos and Royalty-Free Footage - iStock29 Apr 2024 -

Board Certified Behavior Analyst, BCBA, BCBA Fuel, Iced Coffee Lovers, BCBA gifts, Starbucks Cup, bcaba29 Apr 2024

Board Certified Behavior Analyst, BCBA, BCBA Fuel, Iced Coffee Lovers, BCBA gifts, Starbucks Cup, bcaba29 Apr 2024 -

Set Of 3 UV DTF CUP WRAP Transfer Decals For 24oz Cup Wrapping ,Waterproof Rub On Transfer Stickers For Glass Cups And Any Hard Surface ,Clear Film Transfer Paper UV DTF Cup29 Apr 2024

Set Of 3 UV DTF CUP WRAP Transfer Decals For 24oz Cup Wrapping ,Waterproof Rub On Transfer Stickers For Glass Cups And Any Hard Surface ,Clear Film Transfer Paper UV DTF Cup29 Apr 2024 -

Sur La Table Butter Knife29 Apr 2024

Sur La Table Butter Knife29 Apr 2024 -

How to Use Tattoo Paper for Inkjet & Laser Printers - iCraftVinyl29 Apr 2024

How to Use Tattoo Paper for Inkjet & Laser Printers - iCraftVinyl29 Apr 2024