Mould Epoxy Table Tops Guide and Manufacturing Complete Solution

By A Mystery Man Writer

Last updated 01 Jun 2024

M S Klebstoffe - Offering Mould Epoxy Table Tops Guide and Manufacturing Complete Solution Resin Art,Epoxide Resins in New Delhi, Delhi. Also get Epoxy Resins price list from verified companies | ID: 23462108073

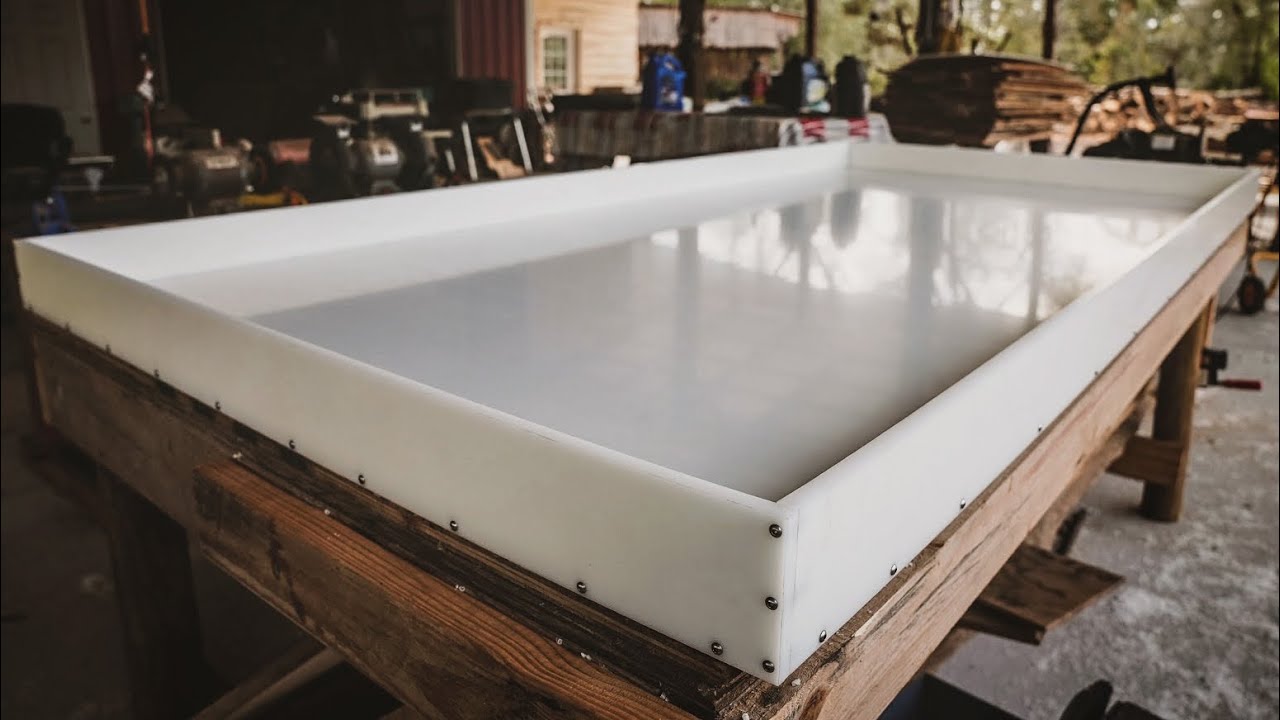

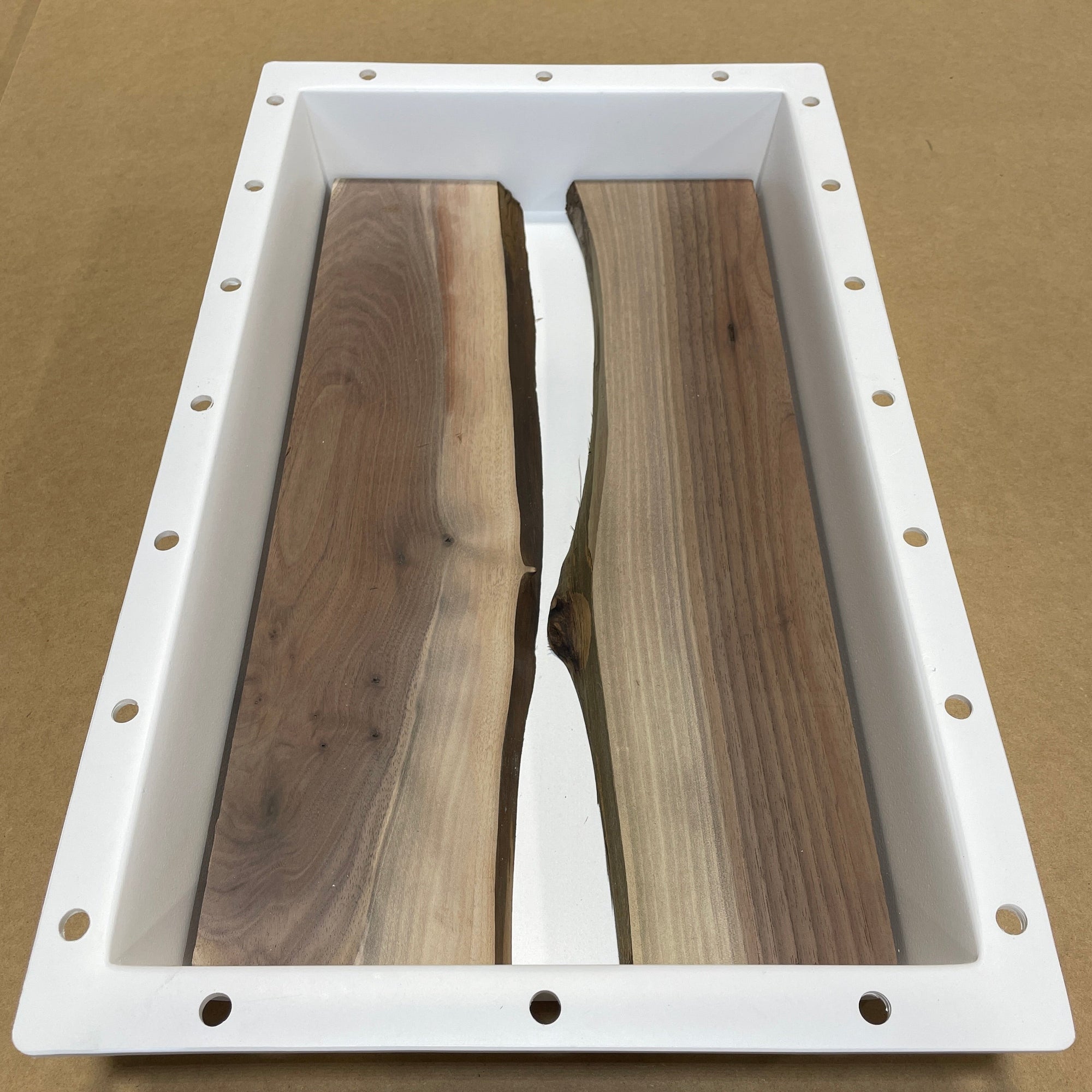

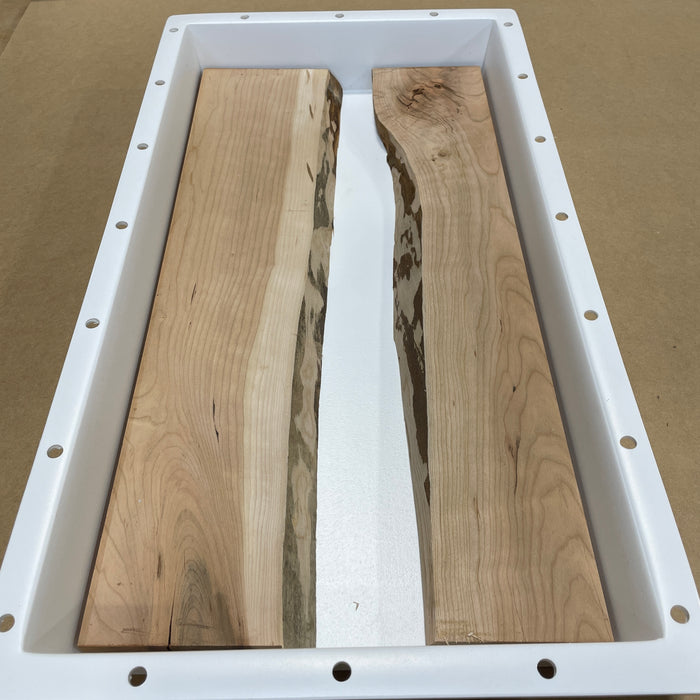

Epoxy tables come in various sizes with different shapes of live edge wood. If you''re starting out on your DIY journey, then you need to read this. Here''s a basic tutorial to help you with your next project and to understand the time and expenses that come with it. Next to each step tells you how many hours you might commit. Each project is different so this part is difficult to gauge.Step 1: (1-2hrs)Research and pick slabs and determine where you''ll cut. It is important to utilize what you can from the slabs with little waste, getting a proper void for the epoxy pour, and also making sure the void is not too excessive. Remember that a larger river = larger volume of epoxy = more money. We recommend Spalted teak for this one, but you can use any slab that suits the style you''re going forStep 2: (1-2hrs)You''ll need to cut the slabs to its proper size then cut or modify some of the branches so it''ll fit properly inside the mold. After cutting, clean up or remove the debris, dirt, or bark.Step 3: (2-3hrs)Depending on the condition of the slabs and the square footage you have to cover, this step could take up to 3 hours. Also, some are more twisted than others. When flattening the slabs, you can use a Virutex Hand Router, a slab flattening mill or your own customized router sled. After flattening, sand the live edge, and be sure to remove all debris.Step 4: (2-3hrs)for example Build mold out of 3/4 thick melamine (Visit your local shop for 4''x8'' sheets of melamine). When finished, this table needs to be 72 x 42. Since the walls will sit on top of the melamine and screwed in from the bottom upward, we need to add 3/4 on each side for the base melamine. There will be 3 parts labeled A, B, C. One A; two B''s; two C''s. A) One base sheet at 73 1/2 x 43 1/2. Side and end caps will be 3 width so that the slab can sit inside of the mold and the epoxy will not overflow. B) Two side caps 73 1/2 length. C) Two end caps 42 length. When all the parts are ready, screw-in from the bottom upward to create a box-like structure. This will be the mold that the slabs will lay inside in. Before adding the slabs, apply silicone/caulk on the seams to seal all areas and prevent any epoxy leakage then let it dry for2-3hours. This step is extremely important because it plays a huge role in whether or not your pour will remain inside of the mold or be wasted through the leaks and end up on the floor. If you don''t let the silicone dry, the epoxy may leak through the wet silicone.Step 5: (2-4hrs)We''ll now proceed with the slab fitting process. First, double-check if the slabs fit the way you want them to inside the mold. This will give you a clearer preview of where the epoxy river will go. If all is fine, remove the slabs from the mold then set it aside.Add a silicone wall (about 1/4 thick/high) along the live edge slabs where the river will run. This will help you with the over pour running all over the slab, at the same time limit epoxy waste. If applicable, we add silicone in the corners, seams, or edges of the slab where the epoxy meets the melamine. Doing this before it gets into the mold will allow the silicone to slightly harden and once tightly fit in the mold, it creates a barrier and prevent the epoxy from seeping in other areas.While these slabs are set to the side, clean the mold of dust and debris. Apply MSK Spanish Epoxy resin in a single pour can go up 50mm thickness.

Epoxy tables come in various sizes with different shapes of live edge wood. If you''re starting out on your DIY journey, then you need to read this. Here''s a basic tutorial to help you with your next project and to understand the time and expenses that come with it. Next to each step tells you how many hours you might commit. Each project is different so this part is difficult to gauge.Step 1: (1-2hrs)Research and pick slabs and determine where you''ll cut. It is important to utilize what you can from the slabs with little waste, getting a proper void for the epoxy pour, and also making sure the void is not too excessive. Remember that a larger river = larger volume of epoxy = more money. We recommend Spalted teak for this one, but you can use any slab that suits the style you''re going forStep 2: (1-2hrs)You''ll need to cut the slabs to its proper size then cut or modify some of the branches so it''ll fit properly inside the mold. After cutting, clean up or remove the debris, dirt, or bark.Step 3: (2-3hrs)Depending on the condition of the slabs and the square footage you have to cover, this step could take up to 3 hours. Also, some are more twisted than others. When flattening the slabs, you can use a Virutex Hand Router, a slab flattening mill or your own customized router sled. After flattening, sand the live edge, and be sure to remove all debris.Step 4: (2-3hrs)for example Build mold out of 3/4 thick melamine (Visit your local shop for 4''x8'' sheets of melamine). When finished, this table needs to be 72 x 42. Since the walls will sit on top of the melamine and screwed in from the bottom upward, we need to add 3/4 on each side for the base melamine. There will be 3 parts labeled A, B, C. One A; two B''s; two C''s. A) One base sheet at 73 1/2 x 43 1/2. Side and end caps will be 3 width so that the slab can sit inside of the mold and the epoxy will not overflow. B) Two side caps 73 1/2 length. C) Two end caps 42 length. When all the parts are ready, screw-in from the bottom upward to create a box-like structure. This will be the mold that the slabs will lay inside in. Before adding the slabs, apply silicone/caulk on the seams to seal all areas and prevent any epoxy leakage then let it dry for2-3hours. This step is extremely important because it plays a huge role in whether or not your pour will remain inside of the mold or be wasted through the leaks and end up on the floor. If you don''t let the silicone dry, the epoxy may leak through the wet silicone.Step 5: (2-4hrs)We''ll now proceed with the slab fitting process. First, double-check if the slabs fit the way you want them to inside the mold. This will give you a clearer preview of where the epoxy river will go. If all is fine, remove the slabs from the mold then set it aside.Add a silicone wall (about 1/4 thick/high) along the live edge slabs where the river will run. This will help you with the over pour running all over the slab, at the same time limit epoxy waste. If applicable, we add silicone in the corners, seams, or edges of the slab where the epoxy meets the melamine. Doing this before it gets into the mold will allow the silicone to slightly harden and once tightly fit in the mold, it creates a barrier and prevent the epoxy from seeping in other areas.While these slabs are set to the side, clean the mold of dust and debris. Apply MSK Spanish Epoxy resin in a single pour can go up 50mm thickness.

Our beginner's guide to deep pour epoxy

Price Intel: How Much Does a Commercial Epoxy Floor Cost?

Epoxy Resins, Grade Standard: Chemical Grade, Packaging Type: Can at Rs 375/kg in Gurugram

Epoxy Resins in Delhi, इपॉक्सी रेजिंस, दिल्ली, Delhi

Crystal Clear & Non Yellowing Epoxy Resin, Coverage: None, Packaging Size: 1.5Kg at Rs 650/kg in New Delhi

Epoxy Resin For Articles, Standard: european standard, Packaging Size: 30kgs at Rs 730/kg in New Delhi

Mould Epoxy Table Tops Guide and Manufacturing Complete Solution

Crystal Clear Epoxy Resin For Table Top, Plastic drum, Coverage: None at Rs 900/kg in New Delhi

Mould Epoxy Table Tops Guide and Manufacturing Complete Solution

POUR ULTRA CLEAR, HIGH GLOSS EPOXY DEEPER THAN EVER for a river table, live edge slab table, counter top, deep-cast sculpture or other thick casting

Deep Pour Epoxy Resin for Epoxy River Tables, Casting Molds, Live Edge Slab Tables & Countertops - Pour Crystal Clear Epoxy 2-3 Deep Per Layer (3

Reconfigurable tooling: Revolutionizing composites manufacturing

Recommended for you

-

Large Resin Table Mold Set 24 Inch Silicone Tray Molds for Epoxy Resin with Tabl01 Jun 2024

Large Resin Table Mold Set 24 Inch Silicone Tray Molds for Epoxy Resin with Tabl01 Jun 2024 -

Large Resin Table Mold Set 24 Inch Silicone Tray Molds for Epoxy Resin with Table Legs for Charcuterie Board, River Table, Coffee Table, Modern Desk01 Jun 2024

Large Resin Table Mold Set 24 Inch Silicone Tray Molds for Epoxy Resin with Table Legs for Charcuterie Board, River Table, Coffee Table, Modern Desk01 Jun 2024 -

How To Make A Reusable HDPE Epoxy Resin Table Mold01 Jun 2024

How To Make A Reusable HDPE Epoxy Resin Table Mold01 Jun 2024 -

1pc Extra Large River Table Resin Molds, 20 Inch XL Round Table Silicone Molds For Big Tray, Clock, Resin Art Creative Fashion Jewelry Casting, Gifts01 Jun 2024

1pc Extra Large River Table Resin Molds, 20 Inch XL Round Table Silicone Molds For Big Tray, Clock, Resin Art Creative Fashion Jewelry Casting, Gifts01 Jun 2024 -

Large Resin Tray Mold Round Epoxy Resin Table Mold Thick Silicone Tray Molds For Charcuterie Board River Table Resin Cas - AliExpress01 Jun 2024

Large Resin Tray Mold Round Epoxy Resin Table Mold Thick Silicone Tray Molds For Charcuterie Board River Table Resin Cas - AliExpress01 Jun 2024 -

There are many ways to make a resin mold for a #resinpour . I find a piece of melamine or wood covered …01 Jun 2024

There are many ways to make a resin mold for a #resinpour . I find a piece of melamine or wood covered …01 Jun 2024 -

Charcuterie Board Epoxy Mold - 30 x 72 (Table) - Hearth & Heart01 Jun 2024

Charcuterie Board Epoxy Mold - 30 x 72 (Table) - Hearth & Heart01 Jun 2024 -

Empire Molds01 Jun 2024

Empire Molds01 Jun 2024 -

18 DIY River Sets — Jeff Mack Supply01 Jun 2024

18 DIY River Sets — Jeff Mack Supply01 Jun 2024 -

Reusable PVC Epoxy Table Mold, Mold for Resin, Epoxy Resin Form, River Table Mold, Epoxy Table Forms, Cheap Epoxy Forms, Mold Alternatives01 Jun 2024

Reusable PVC Epoxy Table Mold, Mold for Resin, Epoxy Resin Form, River Table Mold, Epoxy Table Forms, Cheap Epoxy Forms, Mold Alternatives01 Jun 2024

You may also like

-

Wood carving knives01 Jun 2024

Wood carving knives01 Jun 2024 -

Handysewer Portable Sewing Machine, Handy Sewer, Handy01 Jun 2024

Handysewer Portable Sewing Machine, Handy Sewer, Handy01 Jun 2024 -

Soft Thin Vine Charcoal Sticks, Hobby Lobby01 Jun 2024

-

Rainbow Loom Jewelry Made Easy Step by Step How Tos #626401 Jun 2024

Rainbow Loom Jewelry Made Easy Step by Step How Tos #626401 Jun 2024 -

Full Focus Vinyl Stickers01 Jun 2024

Full Focus Vinyl Stickers01 Jun 2024 -

SCOUT REGALIA – SR Carpenter Pencil01 Jun 2024

SCOUT REGALIA – SR Carpenter Pencil01 Jun 2024 -

6108 3 Digit Zipper Lock And Zipper Tool Used Widely In All Security Purposes Of Zipper Materials., Tools, Steel Tools, Pipe Working Tools, Sharpening Hand Tools, Chain Tools - Rehma Enterprises, Goa01 Jun 2024

6108 3 Digit Zipper Lock And Zipper Tool Used Widely In All Security Purposes Of Zipper Materials., Tools, Steel Tools, Pipe Working Tools, Sharpening Hand Tools, Chain Tools - Rehma Enterprises, Goa01 Jun 2024 -

MYDLO Portable Electric Body Dryer, Full Body Drying Machine with Negative Ion Switch Between On and Cold, Body Air Dryer After Shower : Beauty & Personal Care01 Jun 2024

MYDLO Portable Electric Body Dryer, Full Body Drying Machine with Negative Ion Switch Between On and Cold, Body Air Dryer After Shower : Beauty & Personal Care01 Jun 2024 -

Sidewalk Boston - NEW Paint By Numbers - Paint by numbers for adult01 Jun 2024

Sidewalk Boston - NEW Paint By Numbers - Paint by numbers for adult01 Jun 2024 -

PAINTING A VINTAGE BUFFET Before & After with Fusion Mineral01 Jun 2024

PAINTING A VINTAGE BUFFET Before & After with Fusion Mineral01 Jun 2024