Leveraging CAM for Ultrasonic Knife Cutting

By A Mystery Man Writer

Last updated 10 May 2024

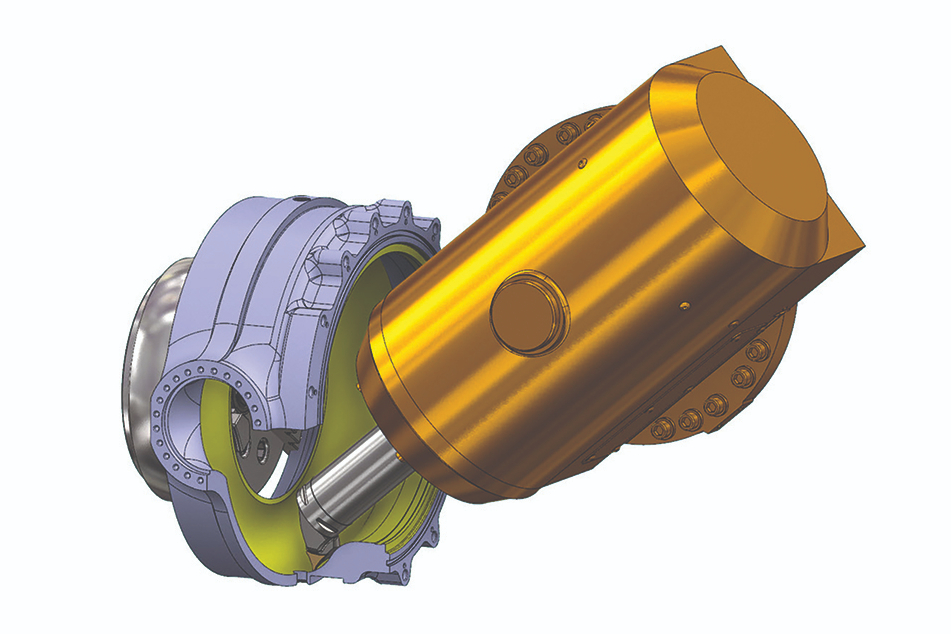

Learn how ultrasonic knife cutting and innovative CAM software like hyperMILL are transforming aerospace manufacturing, reducing waste, and enhancing precision.

Vinyl Cutter Machine, 34 in / 870 mm Max Paper Feed Cutting Plotter, Automatic Camera Contour Cutting LCD Screen Printer w/Stand Adjustable Force and Speed for Sign Making Plotter Cutter

Composites - Aerospace Manufacturing and Design

Milling vs. Grinding for Rapid Stock Removal

Grinding & Deburring

What's Next in Grinding?

Grinding Advances Power Faster, More Efficient Round Solid-Carbide

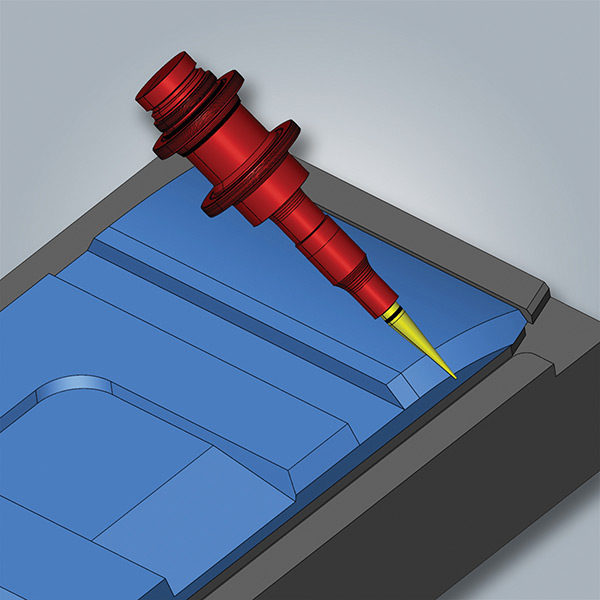

Ultrasonic Cutting, hyperMILL KNIFE Cutting

Grinding Strategies Go from Good to Great

Open Mind CAM Software Provides Ultrasonic Knife Cutting

Composites - Aerospace Manufacturing and Design

Join our May Manufacturing Lunch + Learns - Aerospace Manufacturing and Design

Manual Cutting - MECS Tech Co., Ltd.MECS Tech Co., Ltd.

Milling vs. Grinding for Rapid Stock Removal

Recommended for you

-

369Sonic brings ultrasonic cutting tech to kitchen knives10 May 2024

369Sonic brings ultrasonic cutting tech to kitchen knives10 May 2024 -

China Handheld Ultrasonic Cutter Suppliers, Manufacturers - Best10 May 2024

China Handheld Ultrasonic Cutter Suppliers, Manufacturers - Best10 May 2024 -

30Khz Ultrasonic Cutting Equipment Be Mounted on Robot - Buy10 May 2024

30Khz Ultrasonic Cutting Equipment Be Mounted on Robot - Buy10 May 2024 -

Baguette Cutting by Ultrasonic Knife10 May 2024

Baguette Cutting by Ultrasonic Knife10 May 2024 -

Buy hot 40K Hand Held Ultrasonic Cutter Knife Multi-functional10 May 2024

Buy hot 40K Hand Held Ultrasonic Cutter Knife Multi-functional10 May 2024 -

Using an Ultrasonic Cutter to Make Food Art – Kids Off The Block10 May 2024

Using an Ultrasonic Cutter to Make Food Art – Kids Off The Block10 May 2024 -

35Khz 300W Portable Handheld Ultrasonic Knife For Vulcanized Latex Cutting Machine - AliExpress10 May 2024

35Khz 300W Portable Handheld Ultrasonic Knife For Vulcanized Latex Cutting Machine - AliExpress10 May 2024 -

Cuts Through Plastic Like Butter But It Isn't A Hot Knife - Phrozen Sonic Saber Ultrasonic Cutter10 May 2024

Cuts Through Plastic Like Butter But It Isn't A Hot Knife - Phrozen Sonic Saber Ultrasonic Cutter10 May 2024 -

Customized Ultrasonic Knife Plastic Cutter 35Khz Handheld Transducer Industrial ABS Material Cutting Machine10 May 2024

Customized Ultrasonic Knife Plastic Cutter 35Khz Handheld Transducer Industrial ABS Material Cutting Machine10 May 2024 -

305 Mm Ultrasonic Cutting Blade for Ultrasonic Food Cutting Machine - Buy ultrasonic cutting food, Ultrasonic Cutting Blade, Ultrasonic Food Cutting Machine Product on Professional ultrasonic welding transducer supplier10 May 2024

305 Mm Ultrasonic Cutting Blade for Ultrasonic Food Cutting Machine - Buy ultrasonic cutting food, Ultrasonic Cutting Blade, Ultrasonic Food Cutting Machine Product on Professional ultrasonic welding transducer supplier10 May 2024

You may also like

-

Transparent Colored Rhinestone Design Facial Tattoo Sticker - Temu10 May 2024

Transparent Colored Rhinestone Design Facial Tattoo Sticker - Temu10 May 2024 -

Oxiclean Suds And Clean Car Sprayer : Target10 May 2024

-

INDEXABLE THREADING TOOL INTERNAL 60 DEGREE TIP 8MM, 10MM, 12MM, 16MM, 20MM, 25M10 May 2024

INDEXABLE THREADING TOOL INTERNAL 60 DEGREE TIP 8MM, 10MM, 12MM, 16MM, 20MM, 25M10 May 2024 -

Split Ring Small Key Rings Bulk Split Keychain Rings - Temu10 May 2024

Split Ring Small Key Rings Bulk Split Keychain Rings - Temu10 May 2024 -

Exacto Knives - Which is the best of the three? : r/knives10 May 2024

Exacto Knives - Which is the best of the three? : r/knives10 May 2024 -

Silver Leaf Earrings10 May 2024

Silver Leaf Earrings10 May 2024 -

Reviews for Bondo 8 oz. Fiberglass Resin Repair Kit10 May 2024

Reviews for Bondo 8 oz. Fiberglass Resin Repair Kit10 May 2024 -

Kang the Conqueror (Avengers) Custom Action Figure10 May 2024

Kang the Conqueror (Avengers) Custom Action Figure10 May 2024 -

Lisa Bridge Turquoise Birthstone/Gemstone & Black Sapphire Birthstone/Gemstone Ring Sterling Silver, Women's | Ben Bridge Jewelers10 May 2024

Lisa Bridge Turquoise Birthstone/Gemstone & Black Sapphire Birthstone/Gemstone Ring Sterling Silver, Women's | Ben Bridge Jewelers10 May 2024 -

HNXAZG 10 Rolls Colored Masking Tape, 1 Inch Wide Total 360 Feet10 May 2024

HNXAZG 10 Rolls Colored Masking Tape, 1 Inch Wide Total 360 Feet10 May 2024