Diamond Brite Metals Hemming and Seaming In Metal Processing

By A Mystery Man Writer

Last updated 18 Jun 2024

Hemming and seaming are two similar metalworking processes, where a sheet of metal edge is rolled over and over onto itself until it achieves a tight fit. In hemming, the edge is rolled to itself, while in seaming the edges of two materials are joined. Hems are typically used to reinforce edges, improve the appearance, connect parts together, and to hide burrs and rough edges. Seams are mainly used in the food industry for canned goods, on amusement park rides, and in the automobile industry. He

Hemming and seaming are essentially similar process, where sheet metal edges are rolled over to achieve better appearance and tight fits. Find out more.

Hemming and seaming are essentially similar process, where sheet metal edges are rolled over to achieve better appearance and tight fits. Find out more.

Sheet Metal Hemming, Hem Types & Processes Explained

Stainless Steel Kitchen Backsplash - JTC Metals

Sheet Metal Hemming, Hem Types & Processes Explained

Diamond Brite Metals What is Non-Directional Finish

Petersen Aluminum Corporation, architectural Metals, zinc

Sheet Metal Works MCQ [Free PDF] - Objective Question Answer for

Chapter 5.5 - Starter and Expansion Sets - Wikibooks, open books for an open world

Stainless Steel Kitchen Backsplash - JTC Metals

Sheet Metal Hemming, Hem Types & Processes Explained

Recommended for you

-

OTC 501-078/2 Door Hemming Tool, Left Hand18 Jun 2024

OTC 501-078/2 Door Hemming Tool, Left Hand18 Jun 2024 -

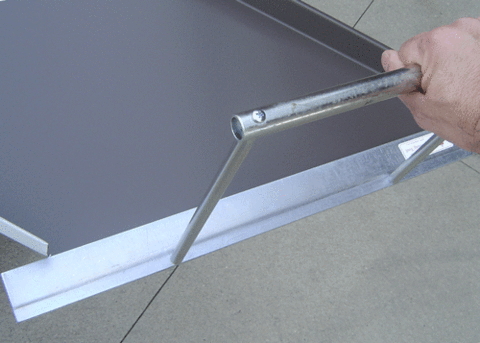

Hemming Tool 24 for Metal Roof Panels Buy Metal Roofing Tools18 Jun 2024

Hemming Tool 24 for Metal Roof Panels Buy Metal Roofing Tools18 Jun 2024 -

press brake hemming tool for flatenning18 Jun 2024

press brake hemming tool for flatenning18 Jun 2024 -

A10 Industrial Sewing Machine Compnts Adjustable Right Angle Thick Cloth Binder Sewing Crafts Hemming Tool Iron Folder 32mm 26mm18 Jun 2024

A10 Industrial Sewing Machine Compnts Adjustable Right Angle Thick Cloth Binder Sewing Crafts Hemming Tool Iron Folder 32mm 26mm18 Jun 2024 -

Press Brake Hemming Tools18 Jun 2024

Press Brake Hemming Tools18 Jun 2024 -

Roller hemming tool 3D model18 Jun 2024

Roller hemming tool 3D model18 Jun 2024 -

Wholesale Cheapest Price Economic China Press Brake Mold Hemming Tool - China Hydraulic Molding Press, Press Brake Mold Hemming Tool18 Jun 2024

Wholesale Cheapest Price Economic China Press Brake Mold Hemming Tool - China Hydraulic Molding Press, Press Brake Mold Hemming Tool18 Jun 2024 -

Edge Guide Hemming Presser Foot for Binders and Hemmers #S70F18 Jun 2024

Edge Guide Hemming Presser Foot for Binders and Hemmers #S70F18 Jun 2024 -

Edge Guide Hemming Presser Foot For Industrial Sewing Machine18 Jun 2024

Edge Guide Hemming Presser Foot For Industrial Sewing Machine18 Jun 2024 -

High Tech Tooling, Press Brake Hemming Tools, Bystronic Hemming Tools, UK18 Jun 2024

High Tech Tooling, Press Brake Hemming Tools, Bystronic Hemming Tools, UK18 Jun 2024

You may also like

-

Milkhouse Candles18 Jun 2024

-

Makeshift Wire Soap Cutter - The Nova Studio18 Jun 2024

Makeshift Wire Soap Cutter - The Nova Studio18 Jun 2024 -

Twisty Glass Blunt Mini — Smokin Js18 Jun 2024

Twisty Glass Blunt Mini — Smokin Js18 Jun 2024 -

Scotch Office Tapes18 Jun 2024

Scotch Office Tapes18 Jun 2024 -

Purse Storage Organizer for Closet, 3 Pack Clear Acrylic Display18 Jun 2024

Purse Storage Organizer for Closet, 3 Pack Clear Acrylic Display18 Jun 2024 -

Flipkart SmartBuy Bucket Spin Mop Floor Cleaning and Mopping18 Jun 2024

Flipkart SmartBuy Bucket Spin Mop Floor Cleaning and Mopping18 Jun 2024 -

Oil Pastels, Set of 12 – Pentel of America, Ltd.18 Jun 2024

Oil Pastels, Set of 12 – Pentel of America, Ltd.18 Jun 2024 -

16 Inch Red Handle Ceremonial Scissors18 Jun 2024

16 Inch Red Handle Ceremonial Scissors18 Jun 2024 -

Wide Royal Blue Clip-On Braces, In stock!18 Jun 2024

Wide Royal Blue Clip-On Braces, In stock!18 Jun 2024 -

We R Memory Keepers Precision Score Board18 Jun 2024

We R Memory Keepers Precision Score Board18 Jun 2024