Fibre Glast - PVA Release Film

By A Mystery Man Writer

Last updated 17 May 2024

PVA, or polyvinyl alcohol, should be used with our #1016 Partall Wax for the easy release of parts from a mold. Wax should be applied to the mold, 3–4 layers thick, and buffed to a high gloss. Once the final layer of wax has dried, PVA should be applied with the following considerations:PVA can be brushed on, but for best results, apply with a spray gun, 12–18 inches away from substrate. Generally, apply in three layers: the first, a thin mist, allowing 10-15 minutes to dry completely.

Experienced fabricators will likely run across that hard-to-separate part, whether it's larger in nature or just stubborn—which presents a challenge for demolding. Standard wedges only reach a few inches into any mold, and using force can result in damage. Applied air pressure provides a solution.Our #958 Air Injected Wedge is designed to deliver air all the way to the sticking point to provide pressure where it is needed most.

Air Injected Wedge

Release Agents - Wax - PVA - Semi-permanent

Molding Fiberglass & Composites - Videos

For final parts and short-run castings, this white Urethane Casting Resin with 75 Shore D hardness can create detailed parts with superior cosmetic qualities. #3475 Urethane Casting Resin has a simple 1:1 mix ratio, and its low mixed viscosity makes it an ideal material to fill complicated molds. Cured castings are bright white and have great physical properties including: good tensile strength and superior stiffness in thin sections.

Fibre Glast - Urethane Casting Resin- 75 Shore D - Quart Kit - 75 Shore D

Mold Releases, Mold Release Spray & Parting Wax

Fibre Glast Low-Temperature Release Film – Lay this perforated film over your laminate or peel ply. After vacuum bagging, the film makes it easier to

Fibre Glast Low Temp Release Film, 1 Yard – Elite Lab Vacuum Bagging Supplies, Degassing Chambers & Vac Purge Kits – Seal & Stabilize Composites Made

This half lamb's wool-half synthetic pad is the best choice when time is a factor. Wool is simply a faster medium when compared to foam. Wool has become more popular as paints are required to contain more solids and fewer solvents. This mix of wool and synthetic is designed to work with our #1102 Step 1 and #1103 Step 2 Mold Polishes, and will withstand the 2500 rpm minimum buffing speed suggested for both.

Fibre Glast Buffing Pads

PVA Release - Barnes Products

Available perforated and non-perforated, our Low Temperature Release Film makes for an easy release of vacuum bagging materials from your part once

Low Temperature Release Film

Cogswell's Molds, Part 2 - KITPLANES

Recommended for you

-

Elmer's Liquid PVA Glue, Washable, White, 118ml Great for Making Slime17 May 2024

Elmer's Liquid PVA Glue, Washable, White, 118ml Great for Making Slime17 May 2024 -

![Chemical structure of polyvinyl alcohol (PVA) [1].](https://www.researchgate.net/publication/323808560/figure/fig1/AS:631581773402120@1527592237154/Figure-1-Chemical-structure-of-polyvinyl-alcohol-PVA-1.png) Chemical structure of polyvinyl alcohol (PVA) [1].17 May 2024

Chemical structure of polyvinyl alcohol (PVA) [1].17 May 2024 -

Factory Wholesale High Grade Clear Glue Brands Polyvinyl Alcohol PVA Powder Pvoh 2488 - China PVA 2488, PVA Thickener17 May 2024

Factory Wholesale High Grade Clear Glue Brands Polyvinyl Alcohol PVA Powder Pvoh 2488 - China PVA 2488, PVA Thickener17 May 2024 -

Polyvinyl Alcohol, Polyvinyl Alcohol Price17 May 2024

Polyvinyl Alcohol, Polyvinyl Alcohol Price17 May 2024 -

PVA Is Plastic (and Used in Laundry Sheets and Pods) — Meliora Cleaning Products17 May 2024

PVA Is Plastic (and Used in Laundry Sheets and Pods) — Meliora Cleaning Products17 May 2024 -

What Is PVA and What Role Does It Play in the Environment? – Fomin Soap17 May 2024

What Is PVA and What Role Does It Play in the Environment? – Fomin Soap17 May 2024 -

KILZ PVA 5 Gal. White Interior Drywall Primer PX01005 - The Home Depot17 May 2024

KILZ PVA 5 Gal. White Interior Drywall Primer PX01005 - The Home Depot17 May 2024 -

PVA: What Is it & How Does Kind Laundry Use It?17 May 2024

PVA: What Is it & How Does Kind Laundry Use It?17 May 2024 -

Ureka, Products17 May 2024

Ureka, Products17 May 2024 -

Coronado PVA Primer – Rossi Paint Stores17 May 2024

Coronado PVA Primer – Rossi Paint Stores17 May 2024

You may also like

-

500pcs Cartoon Animal Teacher Reward Encouragement Motivational17 May 2024

500pcs Cartoon Animal Teacher Reward Encouragement Motivational17 May 2024 -

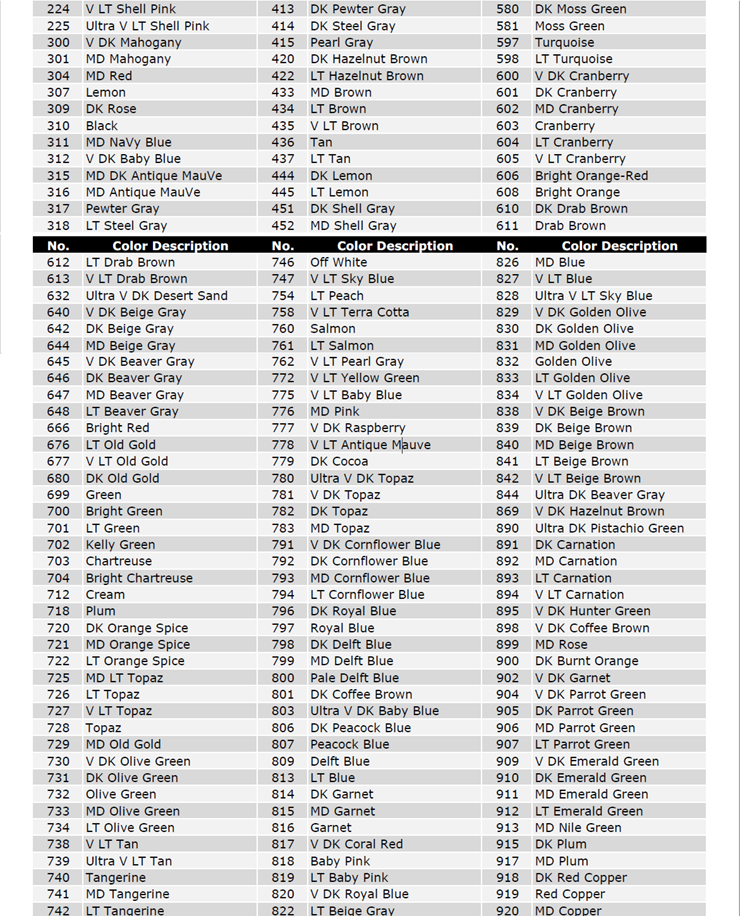

DMC Embroidery Floss Color Description. Cross stitch articles17 May 2024

DMC Embroidery Floss Color Description. Cross stitch articles17 May 2024 -

Forever Laser Transparent No Background for Light17 May 2024

Forever Laser Transparent No Background for Light17 May 2024 -

PRINTABLE FLORAL planner stickers Vintage flower decals Rose17 May 2024

PRINTABLE FLORAL planner stickers Vintage flower decals Rose17 May 2024 -

More Reflective Sewing and Things17 May 2024

More Reflective Sewing and Things17 May 2024 -

Stuff2Color Wizard Lantern - 16x20 Fuzzy Velvet Poster17 May 2024

Stuff2Color Wizard Lantern - 16x20 Fuzzy Velvet Poster17 May 2024 -

DADIFEN 304 Stainless-Steel Eye Pins for Jewelry Making 24 Gauge Silver Head Pins 0.6x40mm 200pcs/Box Open Eye Pins for DIY Making Earring Necklace Bracelets Dangle Charm Jewelry Findings Eyepins17 May 2024

DADIFEN 304 Stainless-Steel Eye Pins for Jewelry Making 24 Gauge Silver Head Pins 0.6x40mm 200pcs/Box Open Eye Pins for DIY Making Earring Necklace Bracelets Dangle Charm Jewelry Findings Eyepins17 May 2024 -

One Taylor Swift-themed Friendship Bracelet Kit17 May 2024

One Taylor Swift-themed Friendship Bracelet Kit17 May 2024 -

seogol Black Sublimation Ink for Epson EcoTank Workforce Printers ET-2720 ET-2760 ET-2750 ET-15000 ET-4700 ET-3760 WF-7710 WF-7720 WF-7210 C88+ ETC.(400ml/Offer Free ICC Printing) : Office Products17 May 2024

seogol Black Sublimation Ink for Epson EcoTank Workforce Printers ET-2720 ET-2760 ET-2750 ET-15000 ET-4700 ET-3760 WF-7710 WF-7720 WF-7210 C88+ ETC.(400ml/Offer Free ICC Printing) : Office Products17 May 2024 -

Glow Art Studio, Glow in the Dark Toy for Kids, Crayola.com17 May 2024

Glow Art Studio, Glow in the Dark Toy for Kids, Crayola.com17 May 2024