Cerakote Firearm Coating - High Temp Ceramic - Caswell Inc

By A Mystery Man Writer

Last updated 18 May 2024

Cerakote%C2%AE%20H-Series%20Ceramic%20Firearm%20Coatings%20Available%20in%204oz%20(120ml)%20Bottles.%20Includes%200.13%20fl%20oz%20(5ml)%20Hardener.%20Covers%20approx%2010%20sq%20ft%20at%201%20mil.%20Designed%20to%20provide%20a%20high-quality%2C%20long-lasting%20finish%20for%20firearms%20and%20firearm%20accessories.%20Cerakote%C2%AE%20H-Series%20coatings%20are%20durable%2C%20corrosion-resistant%20and%20provide%20unparalleled%20levels%20of%20hardness%20and%20adhesion.%20These%20coatings%20are%20also%20resistant%20to%20most%20solvents%20and%20chemicals.The%20foundation%20for%20Cerakote%C2%AE%20H-Series%20coatings%20is%20a%20unique%20ceramic%20technology%20that%20imparts%20both%20flexibility%20and%20excellent%20wear%20resistance%20to%20the%20final%20coating.%20In%20addition%20to%20performance%2C%20the%20Cerakote%C2%AE%20H-%20Series%20line%20of%20products%20is%20designed%20for%20ease%20of%20application.%20Each%20color%20is%20VOC-exempt%20and%20available%20in%20a%20two-component%2C%20oven-cure%20system.%20Prep%20Soak%20each%20metal%20part%20for%2020-30%20minutes%20in%20a%20non-water%20based%20degreaser%20such%20as%20Brake-Kleen%C2%AE%20or%20acetone.%20Spraying%20or%20wiping%20is%20not%20suf%20cient%3B%20soaking%20is%20required.%20Using%20a%20small%20tank%20with%20a%20wire%20basket%20makes%20degreasing%20quick%20and%20easy.%20Place%20the%20screws%2C%20pins%20and%20other%20small%20parts%20in%20a%20smaller%20container%20so%20they%20are%20not%20lost%20during%20the%20soaking%20process.%20Allow%20parts%20to%20air%20dry%20after%20soaking.%20From%20this%20point%20on%20it%20is%20critical%20to%20avoid%20touching%20the%20parts%20with%20your%20bare%20hands.%20Use%20powder-free%20latex%20style%20gloves%20to%20handle%20the%20parts.%20Begin%20by%20plugging%20the%20bore%20at%20both%20the%20chamber%20and%20the%20muzzle%20end%20of%20the%20barrel%20prior%20to%20blasting.%20Grit%20blast%20the%20parts%20with%20%23100%20to%20%23120%20grit%20aluminum%20oxide%20or%20garnet%20sand%20at%2080%20to%20100%20psi.%20Lightly%20blast%20(30-40%20psi)%20non-metal%20parts%20such%20as%3A%20wood%2C%20berglass%2C%20plastic%20or%20polymer.%20For%20anodized%20aluminum%20parts%2C%20set%20the%20blasting%20pressure%20to%2030-40%20psi.%20Strive%20for%20an%20even%20blast%20pattern%20over%20the%20surface%20of%20the%20part.%20Racking%20Hang%20or%20otherwise%20xture%20your%20parts%20so%20that%20you%20can%20access%20all%20the%20surfaces%20of%20each%20part%20with%20your%20HVLP%20gun.%20A%20variety%20of%20metal%20hooks%20in%20multiple%20sizes%20are%20idealfor%20racking%20larger%20parts%2C%20while%20thin%20wire%20or%20alligator%20clips%20are%20ideal%20for%20xturing%20screws%2C%20pins%20and%20other%20small%20parts.%20Gas-Out%20After%20parts%20are%20racked%2C%20heat%20metal%20parts%20in%20the%20oven%20at%20300%20degrees%20Fahrenheit%20(F)%20for%2060%20minutes.%20Gassing%20out%20will%20evaporate%20any%20remaining%20moisture%20and%20solvents%20and%20bring%20any%20remaining%20oils%20to%20the%20surface.Remove%20the%20parts%20from%20the%20oven%20and%20allow%20them%20to%20cool.%20If%20no%20oil%20has%20been%20brought%20to%20the%20surface%2C%20proceed%20to%20Phase%20six.%20Coating%20Preparation%3APrepare%20the%20Cerakote%20for%20application.%20Begin%20by%20vigorously%20shaking%20the%20bottle%20until%20the%20coating%20is%20completely%20mixed%2C%20then%20shake%20some%20more%20for%20good%20measure.%20Determine%20how%20much%20Cerakote%20you%20intend%20to%20use%20before%20mixing%20(see%20table%201%20pg.%2012)%20Pot%20life%20for%20mixed%20Cerakote%20is%20approximately%20two%20hours%20in%20an%20open%20or%20closed%20container.%20Consequently%2C%20mix%20only%20what%20you%20intend%20to%20use%2C%20to%20avoid%20wasted%20coating.%20Spraying%20Blow%20off%20parts%20with%20dry%20compressed%20air%20to%20make%20sure%20there%20is%20no%20trapped%20media%20in%20holes%20or%20pockets.%20Sand%20left%20behind%20will%20cause%20surface%20defects.Start%20spraying%20in%20the%20most%20dif%20cult%20area%20of%20each%20part%2C%20then%20progress%20and%20nish%20to%20the%20easier%20areas.%20This%20should%20help%20avoid%20runs%20and%20thin%20spots.%2020-25%20psi%20is%20recommended%20for%20proper%20application.%20When%20spraying%2C%20strive%20for%20even%20coverage%20(you%20are%20seeking%20a%20half%20thousandth%20to%201%20thousandth%20inch%20coating%20thickness).%20Spray%20with%20suficient%20volume%20so%20that%20the%20Cerakote%20does%20not%20dry%20spray%2C%20which%20is%20when%20the%20coating%20dries%20in%20the%20air%20before%20reaching%20the%20part.%20When%20spraying%2C%20the%20part%20should%20appear%20wet%20but%20not%20so%20wet%20that%20it%20wants%20to%20run.%20Cerakote%20will%20still%20be%20wet%20to%20the%20touch%20until%20it%20is%20oven%20cured.%20If%20you%20touch%20any%20coated%20parts%20before%20curing%2C%20the%20coating%20will%20be%20smudged%20and%20will%20need%20to%20be%20refinished.%20To%20achieve%20the%20recommended%20lm%20thickness%2C%20one%20to%20two%20wet%20coats%20are%20recommended.%20TIPS%20%20Use%20an%20HVLP%20spray%20gun%20with%200.8mm%20tip%20(IWATA%20LPH-80%20recommended)%20Do%20not%20spray%20with%20a%20too%20wide%20pattern%20(i.e.%204-6%E2%82%AC%20pattern).%20Doing%20so%20may%20cause%20dry%20spray%20or%20a%20rough%20nish.%20Spray%20with%20a%202-3%E2%82%AC%20horizontal%20fan%203-5%E2%82%AC%20away%20from%20the%20part.%20Insuficient%20volume%20of%20coating%20being%20applied%20with%20the%202%E2%82%AC%20pattern%20will%20result%20in%20dry%20spray%20or%20a%20rough%20texture.%20%20After%20each%20part%20is%20coated%2C%20set%20it%20aside%20for%20about%20five%20to%20ten%20minutes.%20Cerakote%20will%20still%20be%20wet%20to%20the%20touch%20until%20it%20is%20oven%20cured.%20If%20you%20touch%20any%20coated%20parts%20before%20curing%2C%20the%20coating%20will%20smudge%20and%20will%20have%20to%20be%20refinished.%20Cure%20Schedule%20Options%3A%20%20250%C2%B0F%20for%202%20hours%20300%C2%B0F%20for%201%20hour

Caswell%20Sealer%20Concentrate%20%20Caswell%20Sealer%20%20%20%20is%20a%20fast%20drying%20coating%20that%20penetrates%20porous%20materials%20%20%20%20s

CASWELL SEALER CONCENTRATE - 1 GALLON

Cerakote Firearm Coating - High Temp Ceramic - Caswell Inc

BLING 4 SPEED.lol? - Page 2 - CRF150F/L, CRF230F/L & CRF250F - ThumperTalk

Stainless%20Steel%20Blackener%20370%20is%20an%20acidic%20liquid%20concentrate%20used%20full%20strength%20or%20diluted%20with%20up%20to%203%20parts%20w

STAINLESS STEEL BLACKENER 8OZ

CERAKOTE® (Air Cure C-Series Coating- Our Ceramic Technology Combines Performance with Color on All- Metals, Polymers, More (Armor Black C-192, 4oz Tester) : Automotive

Protect%20Expensive%20Paint%20Jobs%20Before%20Gas%20Tank%20Sealing%20Water%20Based%20Brush%20On%20Masking%20Agent%20Protects%20Your%20Paint%20Job%20Ag

Caswell Seal Mask™ - 8 fl oz

Stainless Steel Polishing Kit - Caswell Inc

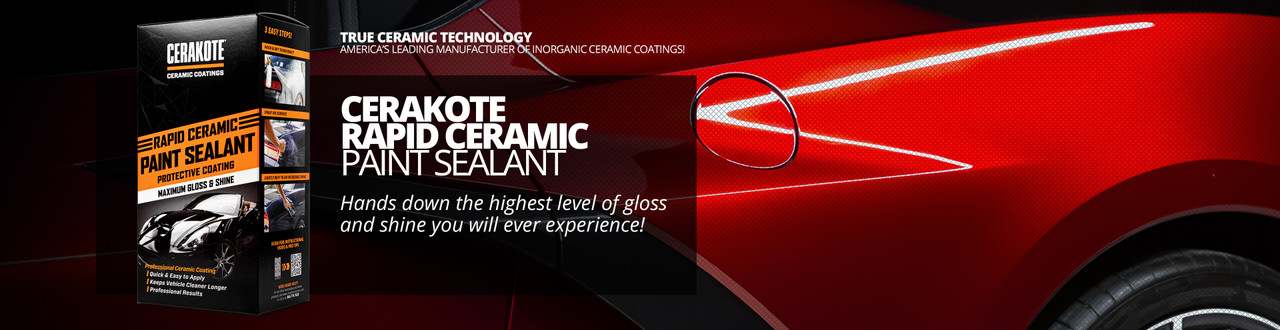

Cerakote Rapid Ceramic Paint Sealant is hands down the highest level of gloss and shine you will ever experience. Achieve mirror-like results in a simple application, right in your own driveway. Cerakote's true ceramic technology repels water, road grime, mud and dirt making your car stay cleaner, longer! Simply wash and dry your vehicle as you normally would. Then evenly spray a light coat directly to a panel or small area of your vehicle.

Cerakote Rapid Ceramic Paint Sealant Kit (8oz bottle) Maximum Gloss & Shine Extremely Hydrophobic Unmatched Slickness - Repels Road Grime Long

BLUE%20CHROMATE%20%20Our%20blue%20chromate%20concentrate%20produces%20a%20true%20blue%20conversion%20coating%20on%20zinc%20plated%20items.%20It%20is%2

BLUE CHROMATE CONCENTRATE - 8OZ

H-245 Socom Blue with C-140 Bright White and MC-156 High Gloss Ceramic Clear by Oregon Timberwolf, LLC

Recommended for you

-

CERAKOTE® Rapid Ceramic Paint Sealant Maximum Strength (12 oz Bottle)18 May 2024

CERAKOTE® Rapid Ceramic Paint Sealant Maximum Strength (12 oz Bottle)18 May 2024 -

Automotive Ceramic Coatings18 May 2024

Automotive Ceramic Coatings18 May 2024 -

Cerakote Ceramic Glass Coat Windshield Kit, AH-PGCKIT0118 May 2024

Cerakote Ceramic Glass Coat Windshield Kit, AH-PGCKIT0118 May 2024 -

CERAKOTE® Rapid Ceramic Paint Sealant Kit (12 oz Bottle) - With Clay Bar Mitt18 May 2024

CERAKOTE® Rapid Ceramic Paint Sealant Kit (12 oz Bottle) - With Clay Bar Mitt18 May 2024 -

CERAKOTE® Rapid Ceramic Paint Sealant – 32 oz. Bulk Pack - Maximum Gloss & Shine – Extremely Hydrophobic – Unmatched Slickness - Pro Results : Automotive18 May 2024

CERAKOTE® Rapid Ceramic Paint Sealant – 32 oz. Bulk Pack - Maximum Gloss & Shine – Extremely Hydrophobic – Unmatched Slickness - Pro Results : Automotive18 May 2024 -

R-GTKIT1004 CERAKOTE TRIM COAT KIT18 May 2024

R-GTKIT1004 CERAKOTE TRIM COAT KIT18 May 2024 -

Cerakote Ceramic Trim Coat, Plastic Trim Restorer, Size: 1 Vehicle Kit18 May 2024

Cerakote Ceramic Trim Coat, Plastic Trim Restorer, Size: 1 Vehicle Kit18 May 2024 -

CERAKOTE® Rapid Ceramic Glass Coat Windshield Kit (8 oz Bottle)– Max Strength Rain Repelling Coating – Easy to Apply – Includes Glass Cleaner – Long18 May 2024

CERAKOTE® Rapid Ceramic Glass Coat Windshield Kit (8 oz Bottle)– Max Strength Rain Repelling Coating – Easy to Apply – Includes Glass Cleaner – Long18 May 2024 -

CERAKOTE® Rapid Ceramic Tire Shine (8oz)18 May 2024

CERAKOTE® Rapid Ceramic Tire Shine (8oz)18 May 2024 -

News Details18 May 2024

News Details18 May 2024

You may also like

-

Vintage Metal Perforator, Paper Puncher, Black Office Hole Puncher18 May 2024

Vintage Metal Perforator, Paper Puncher, Black Office Hole Puncher18 May 2024 -

Picheng 3mm Flat Genuine Leather Cord, 5Yards Strip Cord Braiding18 May 2024

Picheng 3mm Flat Genuine Leather Cord, 5Yards Strip Cord Braiding18 May 2024 -

NATO 50Cal Ammo Box Army Storage Ammunition Surplus Issue Tin Tool Metal 3 Sizes18 May 2024

NATO 50Cal Ammo Box Army Storage Ammunition Surplus Issue Tin Tool Metal 3 Sizes18 May 2024 -

BCW Card House Storage Box18 May 2024

BCW Card House Storage Box18 May 2024 -

Humble Chic Rose Gold Druzy Earrings for Women - Long Threader18 May 2024

Humble Chic Rose Gold Druzy Earrings for Women - Long Threader18 May 2024 -

Play Whe Diamond chart, Lottery numbers, Lottery tips18 May 2024

Play Whe Diamond chart, Lottery numbers, Lottery tips18 May 2024 -

LET'S RESIN 1/2 Gallon Casting Epoxy Resin,Bubble Free & Crystal Clear Epoxy Resin Kit,2 Part Resin and Hardener for Jewelry Making,Crafts,Tumbler,Art18 May 2024

LET'S RESIN 1/2 Gallon Casting Epoxy Resin,Bubble Free & Crystal Clear Epoxy Resin Kit,2 Part Resin and Hardener for Jewelry Making,Crafts,Tumbler,Art18 May 2024 -

Product Test - Suehiro Rust Eraser18 May 2024

Product Test - Suehiro Rust Eraser18 May 2024 -

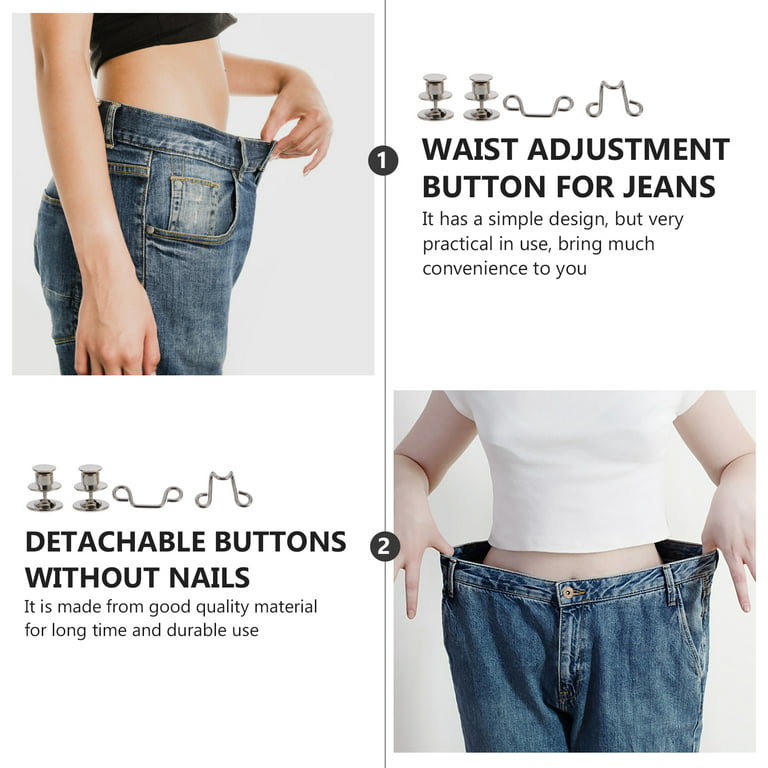

Nuolux Buttons Jeans Waist Button Jean Extenderbuckle Buttons Snap Instant Sewing Hook Button Pants Pant Adjustable Craft, Size: 2.7x0.8cm18 May 2024

Nuolux Buttons Jeans Waist Button Jean Extenderbuckle Buttons Snap Instant Sewing Hook Button Pants Pant Adjustable Craft, Size: 2.7x0.8cm18 May 2024 -

Replacement Bases and Plinth Band. Bakelite Bases. Mahogany Bases.18 May 2024

Replacement Bases and Plinth Band. Bakelite Bases. Mahogany Bases.18 May 2024