Inert Gas Blanketing in Solder Reflow Ovens - Cambridge Sensotec

By A Mystery Man Writer

Last updated 27 May 2024

Inert gas blanketing reduces the risk of oxidisation and improves the reliability and product quality throughout the solder reflow process

Green Hydrogen Analysis - Cambridge Sensotec

The Process of Inert Gas Blanketing - Cambridge Sensotec

EP1511593B1 - Reflow oven gas management system and method - Google Patents

Rapidox 2100-OEM-RSB-WALL - Cambridge Sensotec

Rapidox 7100 Blue Hydrogen Analyser

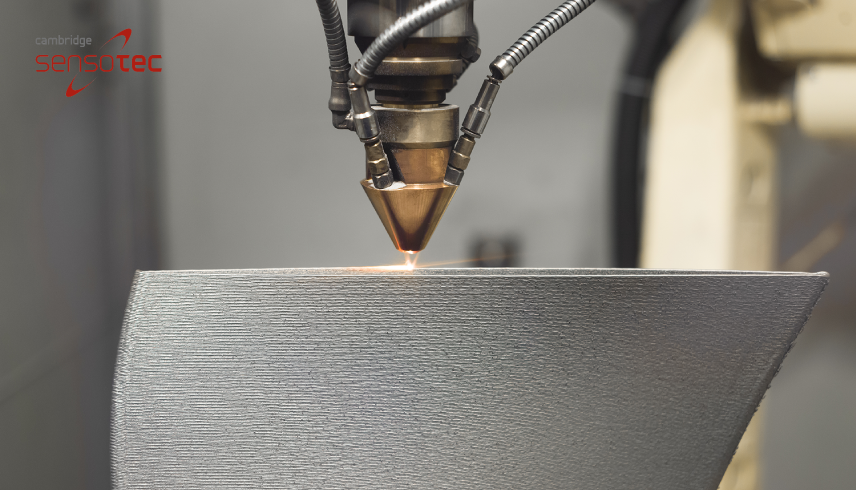

Gas Analysis in Metal Elevating 3D Printing Precision

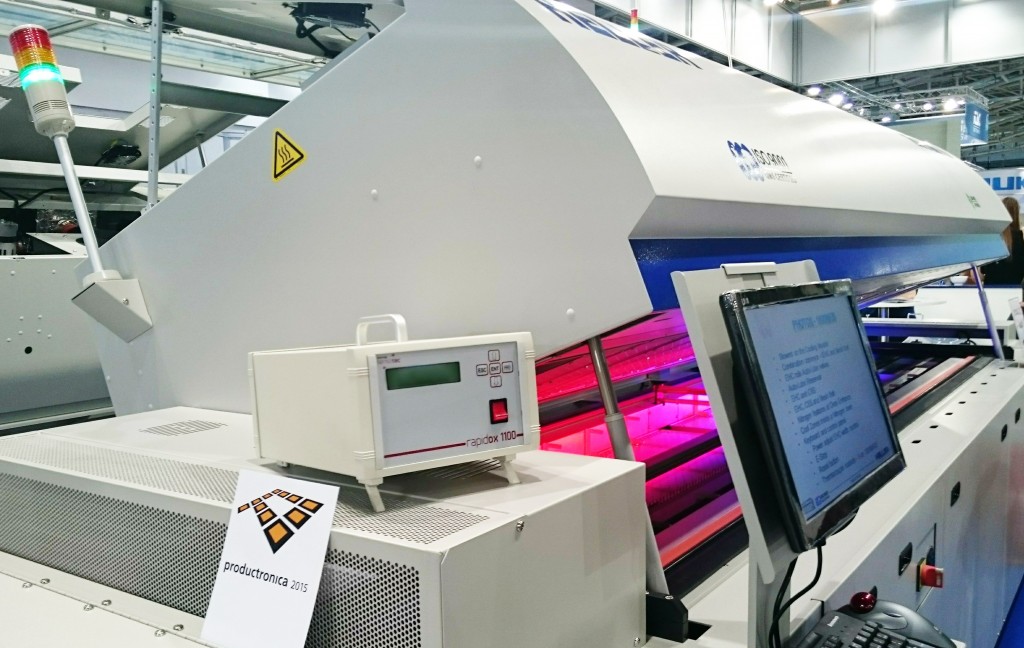

Heller reflow soldering ovens - the proven solution

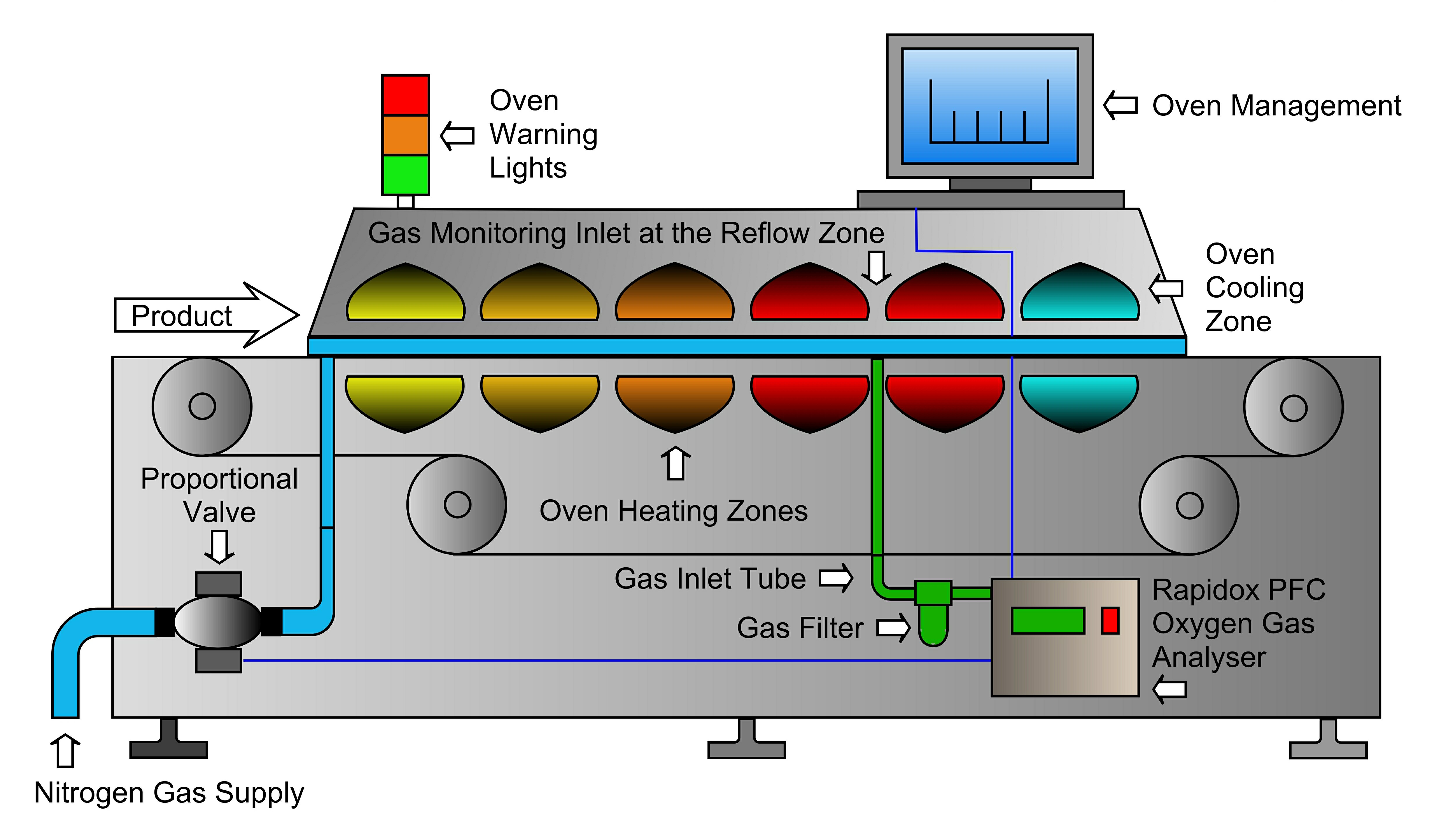

Inert Gas Blanketing in Solder Reflow Ovens - Cambridge Sensotec

Cambridge Sensotec's PFC System in Heller Solder Reflow Ovens

Hydrogen Gas Analysis for Fuel Cells

Recommended for you

-

Reflow Oven, 800W T962 Automatic Reflow Soldering Machine, 180 X 235 Mm Professional Heater, Hot Air Circulation, Eight Temperature Parameter Waves27 May 2024

Reflow Oven, 800W T962 Automatic Reflow Soldering Machine, 180 X 235 Mm Professional Heater, Hot Air Circulation, Eight Temperature Parameter Waves27 May 2024 -

Surface Mount Reflow Oven-A27 May 2024

Surface Mount Reflow Oven-A27 May 2024 -

Precision Lead Free Reflow Oven (AS-5010)27 May 2024

Precision Lead Free Reflow Oven (AS-5010)27 May 2024 -

Reflow Oven With Clarity Screen Zb2520hl Lead-free Reflow Soldering Oven - Welding Nozzles - AliExpress27 May 2024

Reflow Oven With Clarity Screen Zb2520hl Lead-free Reflow Soldering Oven - Welding Nozzles - AliExpress27 May 2024 -

DDM Novastar GF-B-HT High Temperature Mini Reflow Oven27 May 2024

DDM Novastar GF-B-HT High Temperature Mini Reflow Oven27 May 2024 -

Products > SMT Force Convection Nitrogen Reflow Oven - Dou Yee Enterprises27 May 2024

Products > SMT Force Convection Nitrogen Reflow Oven - Dou Yee Enterprises27 May 2024 -

SMT Reflow Ovens for Solder Reflow and Adhesive Curing27 May 2024

SMT Reflow Ovens for Solder Reflow and Adhesive Curing27 May 2024 -

BTU Pyramax 98A 7 Zone Lead Free Reflow Oven - 240V27 May 2024

BTU Pyramax 98A 7 Zone Lead Free Reflow Oven - 240V27 May 2024 -

Formic Reflow Ovens27 May 2024

Formic Reflow Ovens27 May 2024 -

High quality LED SMT SMD Machine Reflow Solder Reflow Oven Welding Machin T-937S27 May 2024

High quality LED SMT SMD Machine Reflow Solder Reflow Oven Welding Machin T-937S27 May 2024

You may also like

-

Buy Wholesale China Erasable Gel Pens - 8pcs Heat Erase Pens For27 May 2024

Buy Wholesale China Erasable Gel Pens - 8pcs Heat Erase Pens For27 May 2024 -

Lace N Loop Reviews - Fight Quality27 May 2024

Lace N Loop Reviews - Fight Quality27 May 2024 -

Hungarian folk stencil,flexible,reusable,125mic,wall decor,home decor, – BO3B27 May 2024

Hungarian folk stencil,flexible,reusable,125mic,wall decor,home decor, – BO3B27 May 2024 -

YRYM HT Candle Dye - 34 Popular Colors Candle Wax Dye for Candle27 May 2024

YRYM HT Candle Dye - 34 Popular Colors Candle Wax Dye for Candle27 May 2024 -

unicorn 145 pieces oil pastel watercolor27 May 2024

unicorn 145 pieces oil pastel watercolor27 May 2024 -

Revol - Pouring Jug 10cm 10cl - Likid Ardoise27 May 2024

Revol - Pouring Jug 10cm 10cl - Likid Ardoise27 May 2024 -

Wire wrapped pure copper bracelet for him or her Unique stranded wire bracelet - Shop Wire Wrap Art Bracelets - Pinkoi27 May 2024

Wire wrapped pure copper bracelet for him or her Unique stranded wire bracelet - Shop Wire Wrap Art Bracelets - Pinkoi27 May 2024 -

![72 Wide 16 Gauge Clear Vinyl 20 Yard Roll - Marine Grade [16GMARINE72-20] - $275.00 : , Burlap for Wedding and Special Events](https://burlapfabric.com/images/167225.jpg) 72 Wide 16 Gauge Clear Vinyl 20 Yard Roll - Marine Grade [16GMARINE72-20] - $275.00 : , Burlap for Wedding and Special Events27 May 2024

72 Wide 16 Gauge Clear Vinyl 20 Yard Roll - Marine Grade [16GMARINE72-20] - $275.00 : , Burlap for Wedding and Special Events27 May 2024 -

New Professional Bottles Cutting Glass Bottle cutter Diy Cut27 May 2024

New Professional Bottles Cutting Glass Bottle cutter Diy Cut27 May 2024 -

Safety Pins Solidarity Made in USA27 May 2024

Safety Pins Solidarity Made in USA27 May 2024